1. The opening of the aluminum alloy template needs to be accurate, and there is no punching deviation and leakage punching phenomenon.

2. For the aluminium formwork to be free from splicing, the following requirements need to be fulfilled: the design of the formwork is accurate, the avoidance of the site installation and the change of the formwork design, and the extension of the assembly and patching time.

3. The production of aluminium formwork is accurate, there is no wrong board or missing board, and the number of supplementary boards and installation finishing is reduced.

4. The force of the aluminium formwork needs to meet the building construction requirements, the support system meets the security inspection requirements, and the civilized construction requirements are met.

5. If there are conditions in the factory production, you can consider the opening of the tension wire hole, the installation of dripping water, and the installation of the pressure groove.

6. The aluminum alloy formwork is packaged accurately, the package number is clear, and the package reflects the requirements of the column number, beam number, and plate number, and is packaged according to the drawing number, which is convenient for accurate material hoisting. When the aluminium formwork arrives at the site, it is necessary to provide a formwork packing list and record the details of the formwork packing.

7. For the recycling of old plates for secondary mold matching, pay attention to controlling the deformation and desoldering of the aluminum template, and find that it needs to be rectified in place.

8. When the design requirement achieves that the inner and outer walls are free of plastering, it is recommended that the outer wall structure be designed as a reinforced concrete shear wall. After waterproofing the bolt holes, the subsequent process construction can be carried out; Thin plastering can also be used for walls; internal insulation should be used as far as possible for thermal insulation.

9. For the secondary mold matching of the recycling template, pay attention to distinguish between the pull tab system, the screw system and the template series.

Now I often hear people talking about the advantages of aluminium formwork, but maybe many people don't know much about such formwork. In fact, aluminum alloy formwork is a brand new building formwork.

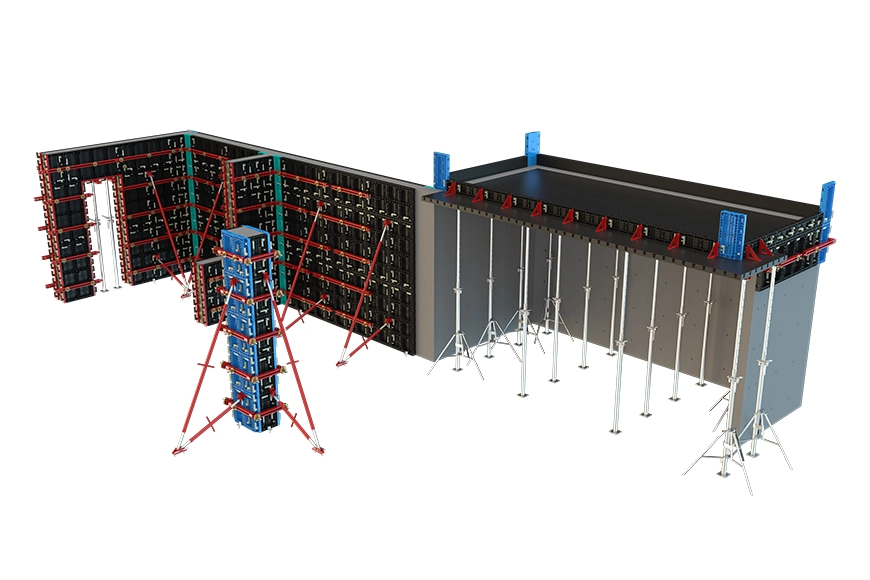

To put it simply, the aluminium formwork is what the previous small steel formwork looked like after the upgrade. It has a very strong advantage in the construction site. The aluminum alloy formwork of the building material can play a new form of the support system, the fastening system, and the accessory system frame. To meet the current social development situation, because the current high-rise and middle-rise buildings are constructed of reinforced concrete, such a closed surface is required to complete the construction.

The construction period of the aluminium formwork is very short, and the construction of one layer can be completed in a few days, so the construction speed of the traditional formwork is many times higher than that of the previous traditional formwork.

Before construction, a detailed analysis of the project and the design of the construction plan should be carried out. After the design is completed, the template will be produced, standardized and serialized. It is very likely that various problems will be encountered during the construction process. Therefore, it is necessary to To a large extent in the design plan to solve.

TECON aluminum alloy formwork has huge advantages. In recent years, in order to have good innovation, reduce some construction work by workers in the building, and improve the quality of the building, it began to use aluminum alloy formwork.