The welding seam at the welding place of the steel template, no matter what the position is, after welding, the welding slag should be cleaned up in time, and the appearance quality of the welding seam should meet the specified requirements, without any welding defects and welding quality problems. This requires the staff to strictly follow the standards during the processing.

During the production and processing of steel formwork, the manufacturer should pay attention to the health of the staff. And the staff should operate in strict accordance with their specifications.

The welding of important and critical parts, procedures, stations and stressed parts of the steel formwork during the processing of the steel formwork must be personally responsible, and necessary precautions must be taken for the processes and parts that often have quality problems during the processing to prevent Unnecessary quality rework.

In the process of steel formwork processing, operators at each station should pay attention to accidental damage to construction personnel, processing equipment, and processed semi-finished products, finished products and accessories, so as to be safe before accidents occur. It must be processed according to the steel formwork processing technology and the material model specifications and size requirements of the construction drawings.

In the process of processing, the processing of the next process should be stopped immediately for the parts that are not clear about the construction, and the next process must be consulted and clarified by the technical personnel at the work site in time.

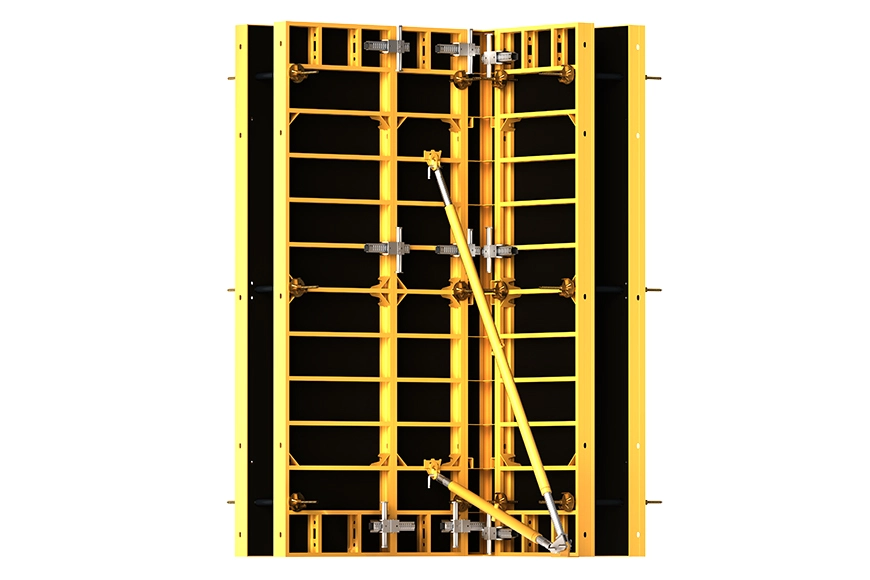

The steel formwork should be subjected to load tests before and during the batch production in the factory to check the comprehensive properties of the formwork such as strength, stiffness and welding quality. When there is a big change in the material or production process of the steel formwork, the load test should be sampled to avoid unnecessary losses.

1. The steel used for the processing of the shaped steel formwork must conform to the steel type standard required for the construction drawing of the steel formwork, and the steel material must conform to the national standard general carbon steel Q235.

2. The face of the material used for the steel mold panel must be flat and smooth, without damage and deformation, and the thickness of the entire panel in the steel mold factory is within the scope of the national standard.

3. For the sheet material used for the processing of shaped steel column formwork, it is forbidden to use the board surface rust (pocket pits), the pockmarked surface or the secondary board with the missing corners and edges of the washboard (shearing and tearing) in the work panel part of the steel mold factory.

4. The angle steel channel steel of the combined rib plate and other shaped steel must be straight without deformation (deformation dead bend), and the ribs at the main stress area of the steel formwork must be made of monolithic materials, and the parts that cannot use monolithic materials such as special-shaped corners and arcs It is necessary to strictly follow the regulations.

5. The welding shrinkage should be reserved for the parts with a large amount of welding when the steel formwork is discharged and blanked. The combined installation and processing of the steel formwork should be processed according to the given scale and modulus of the drawings. The coordinates of the center hole of the steel mold factory are accurate in size and orientation, and it is necessary to ensure the combination accuracy of the steel formwork and the exchange accuracy of the installation process.