During the construction of steel formworks, there are different safety issues to pay attention to. So, what safety measures need to be taken when using cylindrical steel formworks?

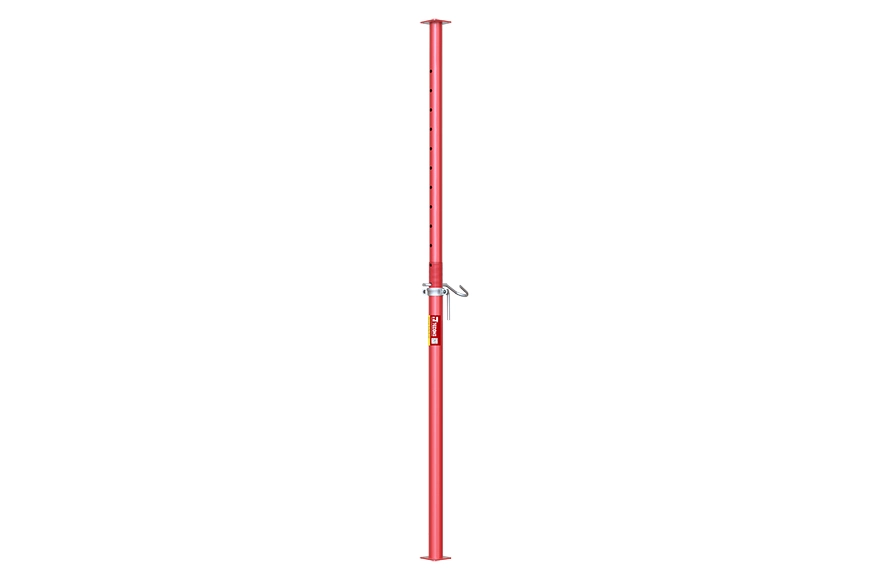

Steel formworks exist for the purpose of being used in cylindrical architecture, mostly for bridge templates and bridge deck formwork. Nowadays, most modern buildings also require the use of cylindrical templates, which have better results than normal square templates. Typically, cylindrical templates are compact and do not require complex procedures, and can be used directly, saving a lot of construction time, which is necessary for most buildings.

Personnel must wear safety helmets when entering the construction site, and safety belts must be tied for work at heights.

When dismantling steel formworks, coordination and teamwork are required, and tools must not be thrown while passing them around.

The placement of the template support should be clean and orderly, and materials should be placed neatly.

Lifting and transferring templates should have someone in charge of directing, and unauthorized operations are prohibited.

Before entering the construction site, all employees should be educated on environmental protection to increase environmental awareness.

Strengthen machinery management and reduce noise during the construction process.

Steel formworks are suitable for different project scales, structural forms, and construction processes, such as on-site assembly, whole lifting, sliding, and climbing. They have a long service life, high component strength, durability, and can quickly circulate. When purchasing steel formworks, pay attention to the following:

Choose a manufacturer with stable product quality and suitable production scale.

Before paying the deposit, carefully review the detailed design and processing drawings of the ordered steel formworks, such as the quantity, specifications, and designed tonnage.

Normal template quotations include taxes and freight, so this should be noted.

As one of the formwork suppliers, our company offers a wide range of ready-made and custom-made products to ensure that we can provide solutions for your construction projects, regardless of size or location. With our professional knowledge of the research and development team, our technical team members will assist on-site as necessary. You can rest assured that our solutions are always cost-effective, and we are always there to support you from the first contact to the completion of construction. Feel free to inquire.