The reinforcement of the circular column formwork is a very important link. To ensure the effect of the construction, we can understand the stress situation and make key reinforcements according to the force analysis.

In order to ensure the turnover of its circular column formwork, ensure that the wooden frame structure is firm, integral and not deformed. The panel is easy to disassemble and install, and is protected by a plastic sleeve at the hole through the wall. The male corner mold at the corner of the wall adopts a removable corner mold, and the internal corner mold adopts a wooden universal corner mold. The outer wall is configured with high and low slabs, the guide wall is limited, the joints between the poured floor slab and the upper wall are tight and smooth, and the structural quality is good.

The new circular column shuttering material for circular column formwork is specially used for the construction of columns. The plan requires that two rows of holes should be reserved at the designated position on the upper part of the cylinder wall during the construction of the circular column formwork, and horizontal rods should be inserted. The horizontal rods are fixed with vertical rods and diagonal braces to form a basic tripod. The wooden tube connecting rod is connected, and the wooden circular column formwork is a new formwork material belonging to the technical field of construction engineering.

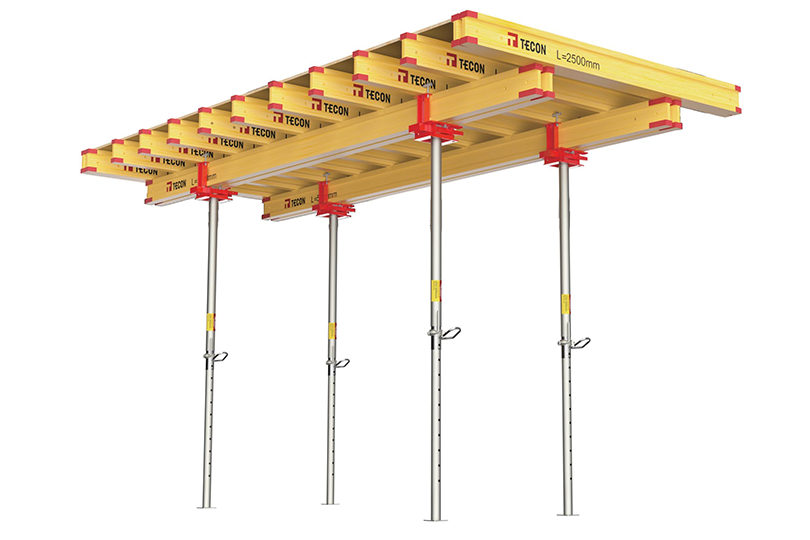

This formwork is a fixed formwork made according to a certain modulus, thus forming a cantilever tripod system. This scheme has high quality requirements for the reserved holes, so the hole-reserving method of prefabricated cement mortar rectangles with holes is adopted.

The wooden building circular column shuttering uses high-quality birch poplar as raw material. The biggest advantage is that it is lighter in weight than ordinary poplar, and has high strength and good toughness. Even a boss with deep pockets worries about the safety of his workers. Second, it will definitely delay the construction work, so there will definitely be a lot of loss for the boss.

Nowadays, every place and every person in the construction industry has begun to accept and even rely on the existence of wooden circular column shuttering. Indeed, it can ensure the safety of every worker and speed up the progress of the project.

The specific method is: prefabricate long squares with cement mortar at the construction site, and fill the round holes with waste cement bag paper (to prevent the cement slurry from flowing in during construction).

According to the requirements of the basic tripod plane layout, the surrounding areas of the sliding platform are marked with nails painted red. When the concrete of the circular column formwork wall is poured to the level, the prefabricated perforated blocks are leveled and straightened at the position of the nails. It is fixed on the wooden wire net of the cylinder wall.

The circular column shuttering on site shall be assembled with wooden strips, fastening bolts, column hoops or fastened wooden corrugations piece by piece piece by piece, and shall be supported and fixed at the same time. This formwork adopts the modular design, can be assembled horizontally and vertically, is flexible in use, has a wide range of applications, and has a relatively complete support system.

The partially damaged circular column formwork can be repaired and used again, and the formwork with a larger damaged area can be shortened and used to extend other formwork. The quality and safety of the wooden circular column formwork is guaranteed, the operation is simple, it is easy to store, and it can be used without worry and effort.