Pre-cast segmented girder beam refers to dividing the entire span of the beam into different segments. After pre-manufacturing in the factory, it is transported to the beam erection site, where the segment assembly machine is used to assemble the segments into holes, completing the hole construction. Currently, there are two methods for producing segmented beams: long-line method and short-line method. Pre-cast segmented girder beam formwork includes long-line pre-cast segmented girder beam formwork and short-line pre-cast segmented girder beam formwork.

The long-line method involves pre-manufacturing all segments on a long base provided by the design that shapes the beam, so that a natural joint surface is formed between the segments.

The short-line method involves pouring each segment onto the same formwork, with one end being a fixed end mold and the other end being a casting beam segment (matching beam). The position of the section to be projected remains unchanged. By adjusting the geometric position of the matching beams poured, the construction method of any prescribed horizontal and vertical curves is obtained. The length of the base only requires 4 to 6 beams.

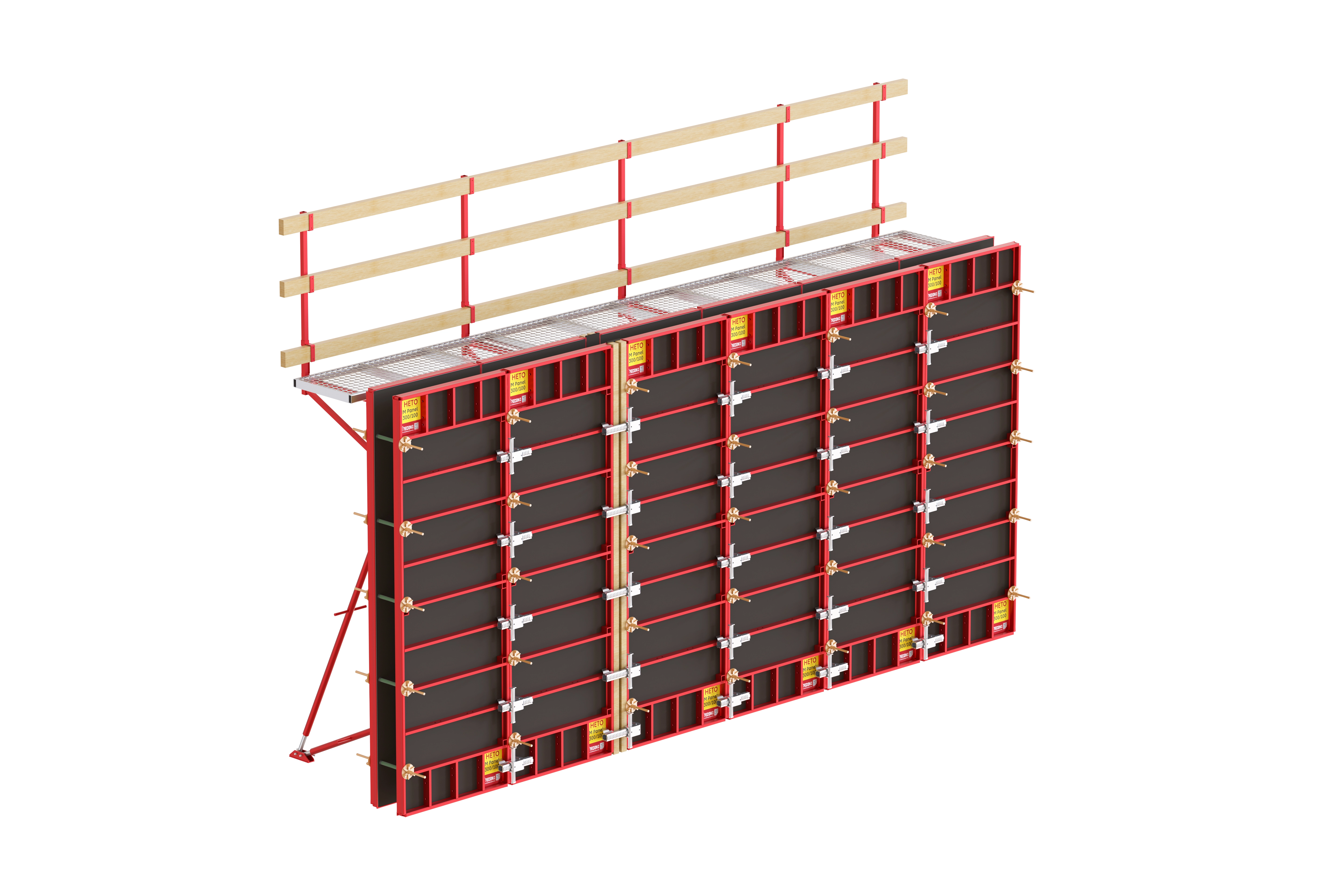

The long-line pre-cast segmented girder beam formwork consists of outer formwork, inner formwork, bottom formwork, end formwork, etc. The formwork is designed in its entirety according to the beam structure, and the formwork is analyzed as a whole.

The outer formwork must have sufficient strength, be able to be demolded as a whole, be easy to support, connect with the bottom formwork reliably, and enable overall longitudinal movement of the outer formwork.

The inner formwork needs to consider the changes in the formwork caused by the variation of section sizes between different segments, and can meet hydraulic demolding requirements. The inner formwork should enable overall longitudinal movement and walking.

The short-line pre-cast segmented girder beam formwork needs to analyze the formwork configuration according to the length, type, and quantity of beam segments, and reasonably configure the formwork. The short-line pre-cast segmented girder beam formwork consists of outer formwork, inner formwork, bottom formwork, bottom formwork trolley, fixed end mold, and fixed end mold support frame.

The fixed end mold serves as a measuring reference for the entire formwork and must ensure that the formwork has sufficient strength and precision. The bottom formwork needs to enable translation and rotation functions and drive the overall longitudinal movement of matching segments. The outer formwork must have sufficient strength, be able to be demolded as a whole, and be easy to support.

For easy matching with the casting segment, including adjustable formwork or other types of formwork systems, the outer formwork should enable micro-adjustment in the transverse and height directions, and can move a certain distance overall longitudinally. The inner formwork needs to consider the changes in the formwork caused by the variation of section sizes between different segments, and can meet hydraulic demolding requirements. The inner formwork should enable overall longitudinal movement and walking.

As one of the leading experts in the field of formwork and scaffolding engineering, our extensive range of off-the-shelf and customized products ensures that we can offer solutions for your construction projects, no matter the size or location. Feel free to contact us for consultation.