The fabricated plastic formwork structure refers to the connection and fixation between the facing material, the decoration component and the building component by means of on-site assembly through connecting pieces or fasteners, or by means of the connection with a tenon joint structure. The fabricated structure can be divided into the skeleton structure, the assembled structure, and the tenon joint structure according to the direct or indirect connection of the decoration material, the decoration component and the building component.

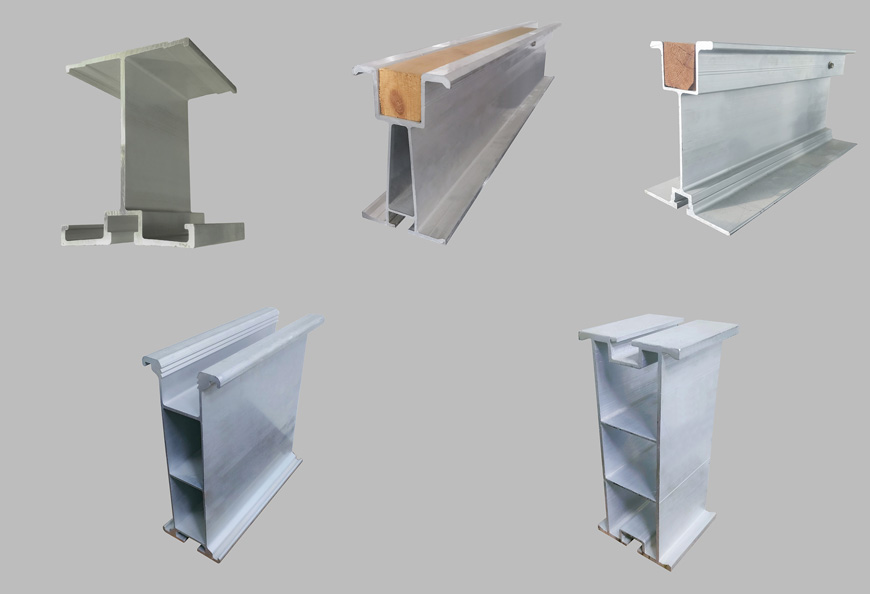

The skeleton structure of the plastic formwork means that the facing materials and decoration components are fixed on the skeleton formed by the assembly of connecting pieces, keels and fasteners by hooking, gluing, nailing, etc., through the skeleton to achieve indirect connection and fixation of building components.

For example, soft film ceiling, dry stone hanging, light steel keel gypsum board ceiling, light steel keel partition wall, light steel keel metal ceiling, light steel keel calcium silica board ceiling, overhead installation of solid wood flooring, etc., through skeletons such as metal keel, wooden keel to realize the connection and fixation with the building components.

The assembled structure of the plastic formwork refers to the way that the facing material and the decoration components are connected and fixed by bolts, screws, round nails and other fasteners through duct corners, hinges, gemel, pins and other connecting parts.

For example, modern panel furniture, finished doors, cabinets, etc. are mostly assembled on-site with standard accessories and custom decoration components provided by manufacturers.

Tenon joint construction refers to the processing of the joint of the material into a tenon, a mortise or a tenon groove. Through the joint of the tenon and the mortise or tenon and groove, the tenon is nailed into the draw pin, and the connection and fixation between material and the component are realized by the friction between the materials.

For example, Chinese traditional wood structure buildings and traditional furniture are mostly constructed with tenon joints, and some modern framed furniture also use this method.

Common tenon joint structures include open tenon, closed tenon, round tenon, square tenon, dovetail tenon, single tenon, multiple tenon and so on. The connection and fixation methods of the fabricated plastic construction formwork structure mainly include: nailing, pinning, tenoning, riveting, hooking, hanging, clamping, welding, gluing, bolting, etc. The fabricated structure is widely used, and it is also the main direction for the development of decoration projects in the future, and is developing in a more intensive and integrated direction. The on-site installation of decoration components will become easier.

As one of the leading experts in the field of formwork and scaffolding engineering, Suzhou TECON Construction Technology Co., Ltd., has a wide range of ready-made and customized products so as to ensure that we can provide solutions for your construction projects, regardless of its scale or location. If necessary, please consult.