Now there are some concrete circular columns using PVC plastic pipes on construction sites, so what is the difference between PVC plastic pipes and circular column timber formwork? What should we pay attention to when using it for the first time?

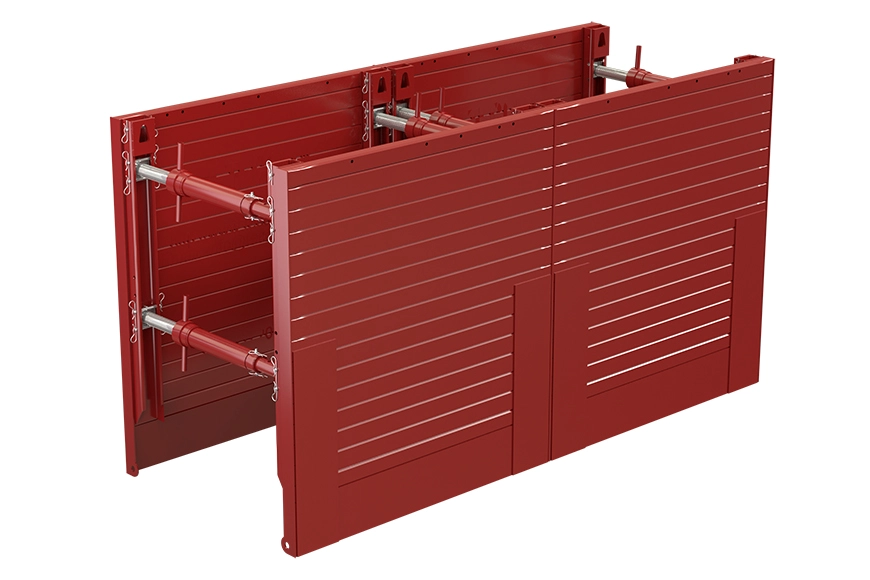

(1) It is not easy to remove the PVC plastic pipe. In terms of the construction and removal, however, it is easy to remove the circular column timber formwork. After removal, the column can achieve the effect of a clear water formwork, while the PVC plastic pipe is a closed pipe, which is difficult to be removed. The circular column timber formwork is firm in texture, and the turnover times are generally more than 10 times, while the turnover times of plastic pipe is less. Many construction units use it as a formwork for one-time small column formwork construction.

(2) Professionally, circular column timber formwork is specially used for column concrete formwork construction. PE or PVC plastic pipes are often used as sewage pipes or rainwater pipes for drainage or water supply, and their bearing capacity of wall pressure is limited. Effective agitation cannot be achieved in the concrete pouring process, there will be bubbles in the poured column, and the quality of the poured column cannot be guaranteed, and the column is often used as a support, which is very unsafe.

(3) In terms of safety, the pressure bearing capacity of the plastic pipe is not as good as that of the circular column timber formwork. The formwork may burst during the pouring process. The plastic pipe will become brittle in winter and be easily damaged.

(4) As for price, small-diameter plastic pipes are cheaper than circular column timber formwork, but in terms of large-diameter column formwork construction, the price of plastic pipes will be greatly increased, and the cost performance is low.

When the circular column timber formwork is used for the first time, many customers are overwhelmed, because most of the steel formwork is used before, and there is no experience in using the circular column timber formwork.

The factory height of the circular column timber formwork is generally three meters. If you encounter a five-meter column, the circular column timber formwork must be installed in a dislocation. You can first close the two formwork with iron wire, and then use the matching fixed steel belt to reinforce it. The average spacing of the steel belts is 25cm to 30cm each.

After the circular column timber formwork is closed and reinforced, the bottom circular plane of the formwork should preferably be 0.5 to 1cm away from the ground, and then fill the joints with concrete to ensure that there will be no leakage of grout.

After the circular column timber formwork is installed, in order to protect the formwork, you should first add four wooden squares of 5*10cm around it, and then fix the wooden squares with steel pipes at a distance of 50 to 100cm above the wooden squares for the vertical positioning of the circular column timber formwork.

The parts where the upper and lower connectors of the two circular column timber formwork are installed are reinforced with fixed steel belts to avoid the leakage of grout. In the case of circular column timber formwork with a diameter of less than 1 meter and the column within seven meters, the concrete pouring can be finished at one time. If it is more than seven meters, it is recommended to divide the concrete pouring into two times. The second pouring is carried out 30 to 60 minutes after the first pouring.