The full name of aluminium alloy formwork is concrete engineering aluminium alloy formwork, which is a new generation formwork system after wood formwork, bamboo, wood plywood and steel formwork.

The aluminium alloy formwork is made of aluminium alloy profiles as the main material, which is suitable for concrete projects made by machining and welding processes, and is designed according to the 50mm modulus. equipment combined. The design and construction application of aluminium alloy formwork is an innovation in the technology of concrete engineering formwork, it is also the promotion of prefabricated concrete technology, and it is also the embodiment of the industrialization of production technology.

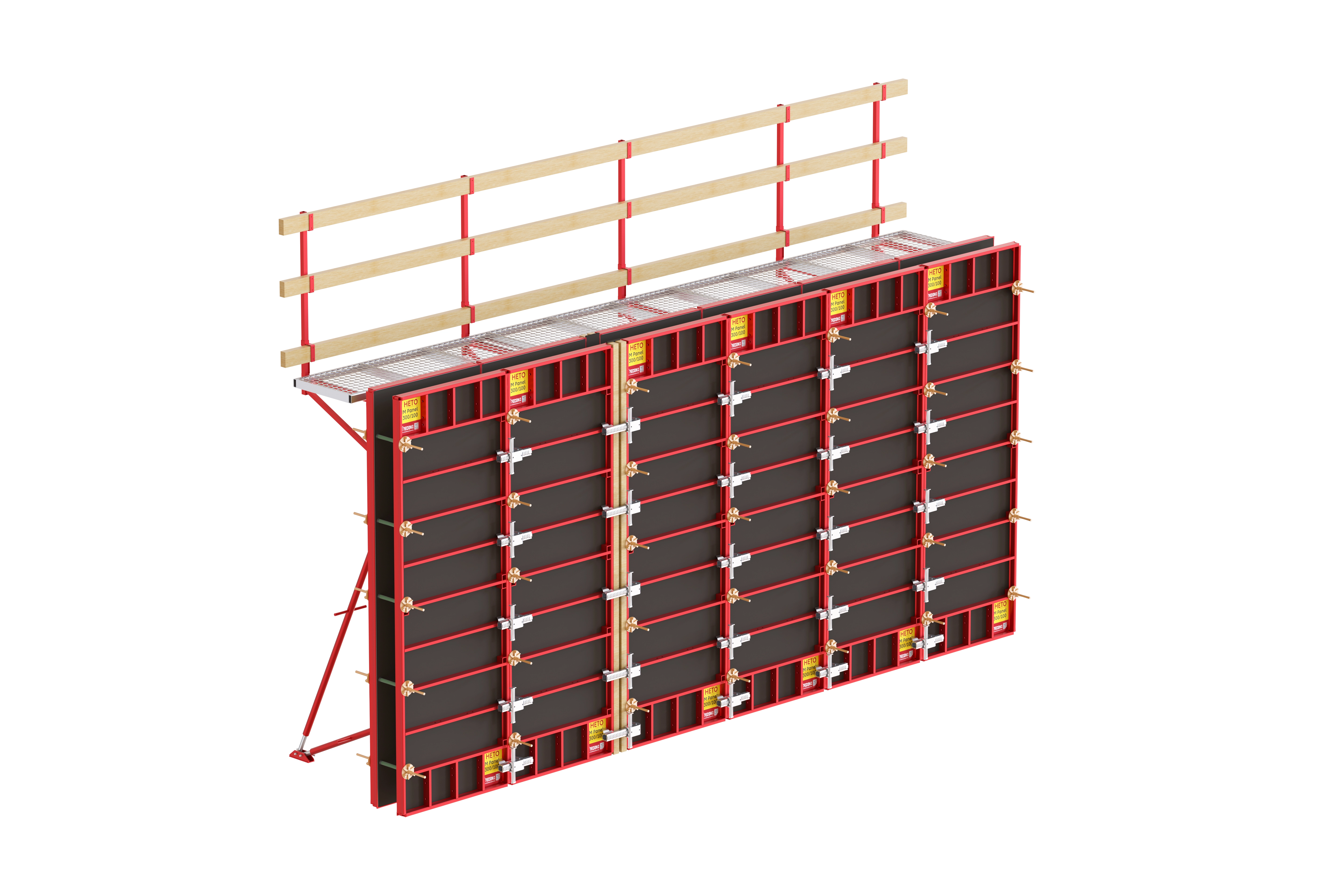

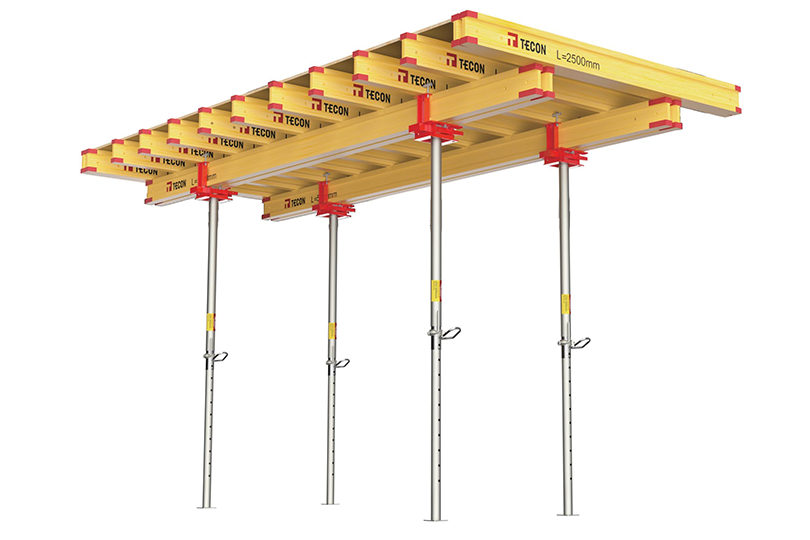

The aluminium alloy formwork consists of four parts: the formwork system, the fastening system, the support system and the accessory system. It has a complete supporting formwork system and is suitable for formwork systems of different structures.

Aluminium alloy formwork is divided into plane formwork, corner formwork and components according to the structural form. Among them, the corner formwork includes an external corner formwork, an internal corner formwork and an internal corner formwork, and the components include a single inclined aluminium beam, a double inclined aluminium beam, a floor slab early dismantling head, and a beam bottom early dismantling head.

Aluminium alloy formwork is divided into standard formwork and non-standard formwork according to the general form. Rectangular flat plates, corner templates and common components with the same shape that fit the height of the side rib of 65mm, the hole diameter of 16.5mm, the distance between the hole center and the panel is 40mm, and the length, width, and hole center distance are in accordance with an integer multiple of 50mm, all of which are standard plates. Templates or components that do not meet one of the above conditions are non-standard templates. Non-rectangular formwork and non-conventional components are not included in the marking scale of the above-mentioned standard and non-standard parts.

In recent years, as people pay more and more attention to low carbon and energy saving advocated by the society, people have turned their attention to metal aluminium alloy formwork, and the application of green aluminium alloy formwork with significant energy saving and emission reduction in buildings will be promising.

Compared with the traditional formwork process, the aluminium formwork system has the following advantages:

1. The construction period is short. The aluminium formwork system is a quick-release formwork system. The normal construction of a set of formwork can reach one floor in four days, and the pipeline construction can be carried out well, which greatly improves the construction progress and saves management costs.

2. The number of repeated uses is large, and the average cost of use is low. The aluminium formwork system uses the aluminium alloy profile formed by the overall extrusion as the raw material, and a set of formwork standard construction can be turned over and used more than 300 times. The purchase price of a set of templates is evenly amortized, which saves a lot of cost compared with traditional templates.

3. The construction is convenient and efficient. The aluminium formwork system is simple and convenient to assemble, with an average weight of about 20kg. It is completely handled and assembled manually, without the assistance of any mechanical equipment, and the system design is simple. Skilled installation workers can install 20-30 square meters per person per day, which greatly saves labor costs.

4. Good stability and high bearing capacity. The bearing capacity of most aluminium formwork systems can reach 60KN per square meter, which is enough to meet the formwork bearing capacity requirements of most residential buildings.

5. Wide application range. aluminium formwork is suitable for the use of walls, horizontal floors, columns, beams, stairs, window sills, floating boards, etc., and is still useful for secondary structural forms such as ring beams, structural columns, and anti-sills.

6. Fewer joints, high precision, and good concrete surface effect after formwork removal. After the aluminium building formwork is removed, the quality of the concrete surface is smooth and clean, which can basically meet the requirements of fair-faced concrete.

7. There is less construction waste on site, and the support system is simple. All parts of the aluminium formwork system can be reused. After the construction is removed, there is no garbage on site. The support system has a simple structure and is easy to dismantle, so the entire construction environment is safe, clean and tidy.

8. Standard and versatile. There are many specifications of aluminium formwork, which can be assembled with different specifications according to the project; when the used formwork is rebuilt into a new building, only about 20% of the non-standard plates need to be replaced, which can reduce the cost.

9. High recycling value. After the aluminium formwork is scrapped, when the residual value of the waste treatment is high, the advantage of the amortized cost is obvious.

10. Low carbon emission reduction. All materials of the aluminium formwork system are renewable materials, which conform to the national regulations on energy conservation, environmental protection, low carbon and emission reduction of construction projects.