As an important construction procedure of cast-in-place reinforced concrete, the formwork project plays a decisive role in ensuring the construction progress and controlling the construction quality of the reinforced concrete structure, and is also one of the important considerations for project cost control.

At present, the formwork used in the construction industry mainly includes steel formwork system, wood formwork, bamboo formwork and plastic shuttering panels. Steel formwork is cumbersome, difficult to handle, and has low production efficiency; wood formwork and bamboo formwork are insufficient in output and cannot be regenerated, resulting in a lot of deforestation, destruction of ecological environment and waste of resources; plastic formwork is simple to process and can be recycled, but solid It is heavy, easy to warp and deform, which affects the quality of the project, and the foam is easy to absorb water, which increases the amount of engineering labor.

The green ecological hollow plastic formwork is extruded with nano-filler treated with special surface modification and additives with specific structure, and the targeted functional nano-masterbatch is prepared by extrusion, and modified polypropylene (PP) recycled material with other fillers , its tensile strength and flexural modulus are as high as 19.6MPa and 1,669MPa respectively; try to develop hollow plastic building formwork with modified PP recycled material, and finally succeeded by three-layer co-extrusion one-step method on the basis of optimizing the design of extrusion die structure Developed the fifth-generation product that fully meets the requirements of the construction industry - a new type of hollow plastic building formwork.

Its flexural modulus is as high as 2,200MPa or more. The unique hollow and white skin and black core structure design of the template are neatly arranged according to the principle of mechanical structure. The black material is cheap, heat-absorbing, and has high rigidity. It reduces the cost and reduces the warping deformation (<2mm) caused by thermal expansion and contraction, and ensures the quality of the template while the waste is used.

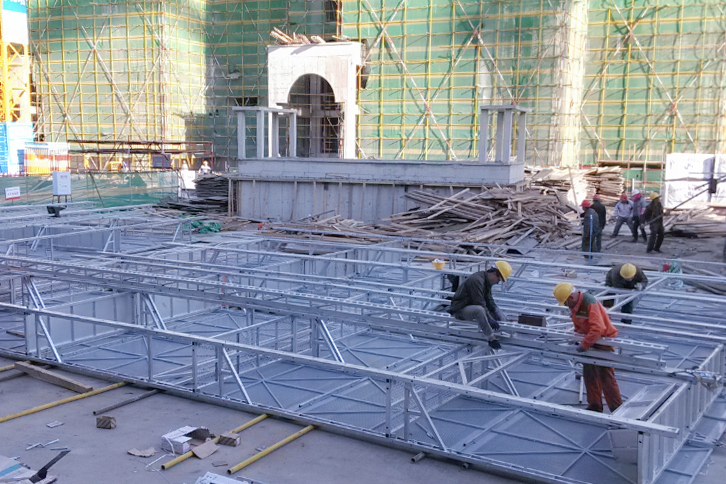

In addition, the developed formwork is a new type of building product that is different from steel, wood, aluminum alloy and other building formwork, and has advantages that other formwork does not have.

1. If the surface flatness exceeds the requirements of the current concrete construction process, the surface is smooth and clean, no release agent is required, cleaning and maintenance costs are reduced, and the chemical properties are excellent.

2. It has no moisture absorption, no mildew, cold resistance, high temperature resistance, acid resistance, alkali resistance, flame retardant, no cracking, large plate width, less seams, easy demoulding, can be processed into any length, etc., especially suitable for underground and humid used in the environment.

3. Light weight, convenient formwork dismantling, low labor intensity for handling operations, and high construction efficiency.

4. The hollow plastic template has high strength, good toughness, strong elasticity, impact resistance, wear resistance, long service life, more than 50 cycles of use, and the weight gain after use is less than 5‰.

5. Good workability, can be planed, sawed, nailed, and can be used together with wooden formwork.

6. It can greatly improve the quality of construction projects.

7. The scraps cut during the production and construction process and the templates that exceed the maximum number of cycles can be directly recycled and crushed into PP recycled materials, which can be reused to produce new templates after modification.

It is produced from all waste and can be recycled and regenerated. It is a green ecological material, which not only protects the forest, but also reduces white pollution. building materials.