What is the quality management system of aluminium formwork? Next, the engineering staff of aluminium formwork manufacturers will specifically talk about the quality management of aluminium formwork.

1. Adhere to the certification system

Relevant personnel in special positions (measurement, testing, etc.) must be trained to obtain a qualification certificate and a job certificate before they can take up the job.

2. Adhere to the "three inspection system"

The project quality objectives have been established and implemented during the construction process. Adhere to the implementation of the "self-inspection, special inspection, handover inspection" system, and never leave problems and hidden dangers to the next process. The construction quality of various types of work, procedures, and sub-item projects, as well as the entry of materials, construction tests, changes to drawings, processing orders, construction plans and technical measures are strictly implemented in this system, so as to find problems as soon as possible and solve them in time.

3. Adhere to the technology first system

Before the start of the project, the technical department shall make a disclosure to the construction management personnel, team leaders, etc. on the key issues of the technical quality points of the entire project. Before the construction of the sub-project aluminum membrane panels, the foreman is responsible for the technical quality disclosure work to the team leader and the team leader to the team members. The disclosure work shall be mainly in written form, and construction shall not be carried out without disclosure. For key processes and key parts, the foreman shall be responsible for on-site determination and verification, and the technical department shall review and supervise each key link and important process, and solve problems in a timely manner.

4. Adhere to the quality regular meeting system

In regular or irregular production meetings, while arranging production plans, adhere to quality work arrangements. Special quality meetings are held regularly, and production managers and full-time quality inspectors at the construction site present quality dynamic reports, and study and formulate quality work plans and countermeasures.

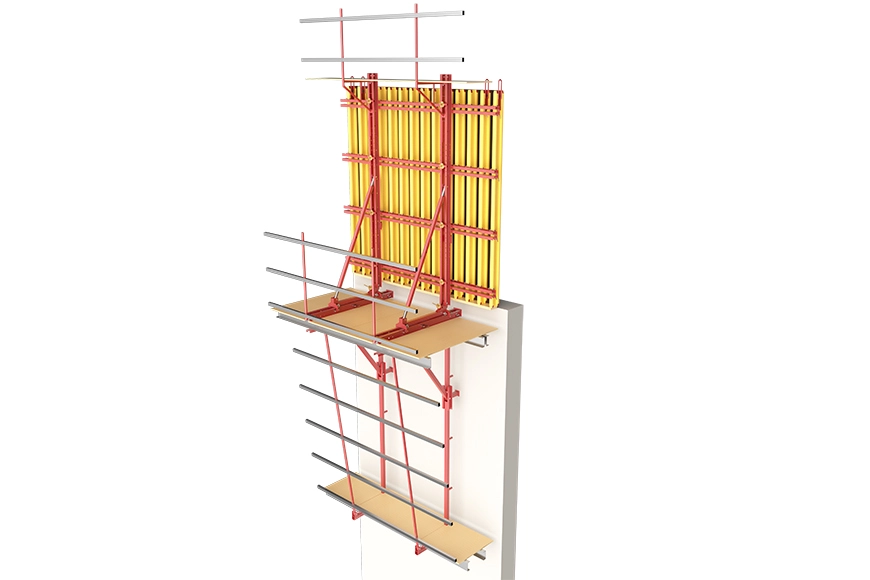

With the wider application of aluminium formwork, the insufficiency of the traditional way of reinforcing the pull-screw is gradually emerging.

The traditional reinforcement of the tension screw, the cement support bar on the inner side of the formwork, the steel back corrugation on the outer side of the formwork, and the tension screw to ensure the thickness of the concrete wall, so the requirements for the construction process of the construction team are stricter, and the nuts at both ends of the screw are pre-tightened. If the force is too high, the cement support strip on the inner side of the formwork will be damaged, resulting in insufficient wall thickness. If the pre-tightening force of the nuts at both ends of the screw is too small, the nuts will loosen during the vibrating process of the pouring construction, and the wall thickness will increase, which also cannot meet the design requirements.

The reinforcement of the pull tab depends on the holes at both ends of the steel pull tab and the frame holes of the aluminium formwork on both sides of the wall. At the same time, the pinning ensures the thickness of the wall to ensure the quality of concrete forming, and is less affected by human factors during the construction process.

The preparation process of aluminum alloy formwork manufacturers: selection of reinforcement system → selection of profiles → construction of design team → selection of standard components of aluminium formwork → formulation of production process flow → selection and procurement of equipment and molds → pre-job preparation for production teams.

At the beginning of the preparation of the aluminium formwork, the reinforcement system of the aluminium formwork must first be selected. In the early stage of China's aluminium formwork, the pulling screws were mostly used, and the pulling tabs were gradually becoming the mainstream in the later period.