The common problems with cylindrical steel formwork are inaccurate section size, excessive concrete protective layer, and twisted column body.

The preventive measures are to follow the positioning lines on the design drawings before erecting the formwork, correct the rebar position, and make small square plate steel formwork for the base of the column. The size and spacing of column hoops should be designed according to column section size and height, and support and tie rods should be provided for the four corners of the column.

The common problems with beam and slab steel formwork, such as uneven beam surface, uneven bottom, bulging side, oversized beam top opening, and sagging midsection of the slab, can be effectively addressed by using specialized formwork for beams columns and slabs.

The preventive measures are to design the sizes and spacing of joists and supports for the beam and slab steel formwork, so that the support system has sufficient strength and stiffness to prevent deformation of the formwork during concrete pouring. The bottom of the steel formwork support should be supported on a solid ground and padded with long footboards to prevent sinking. The beam and slab steel formwork should be arched according to the design requirements to prevent excessive deflection. The locking rods should be added to the upper opening of the bridge formwork to prevent deformation.

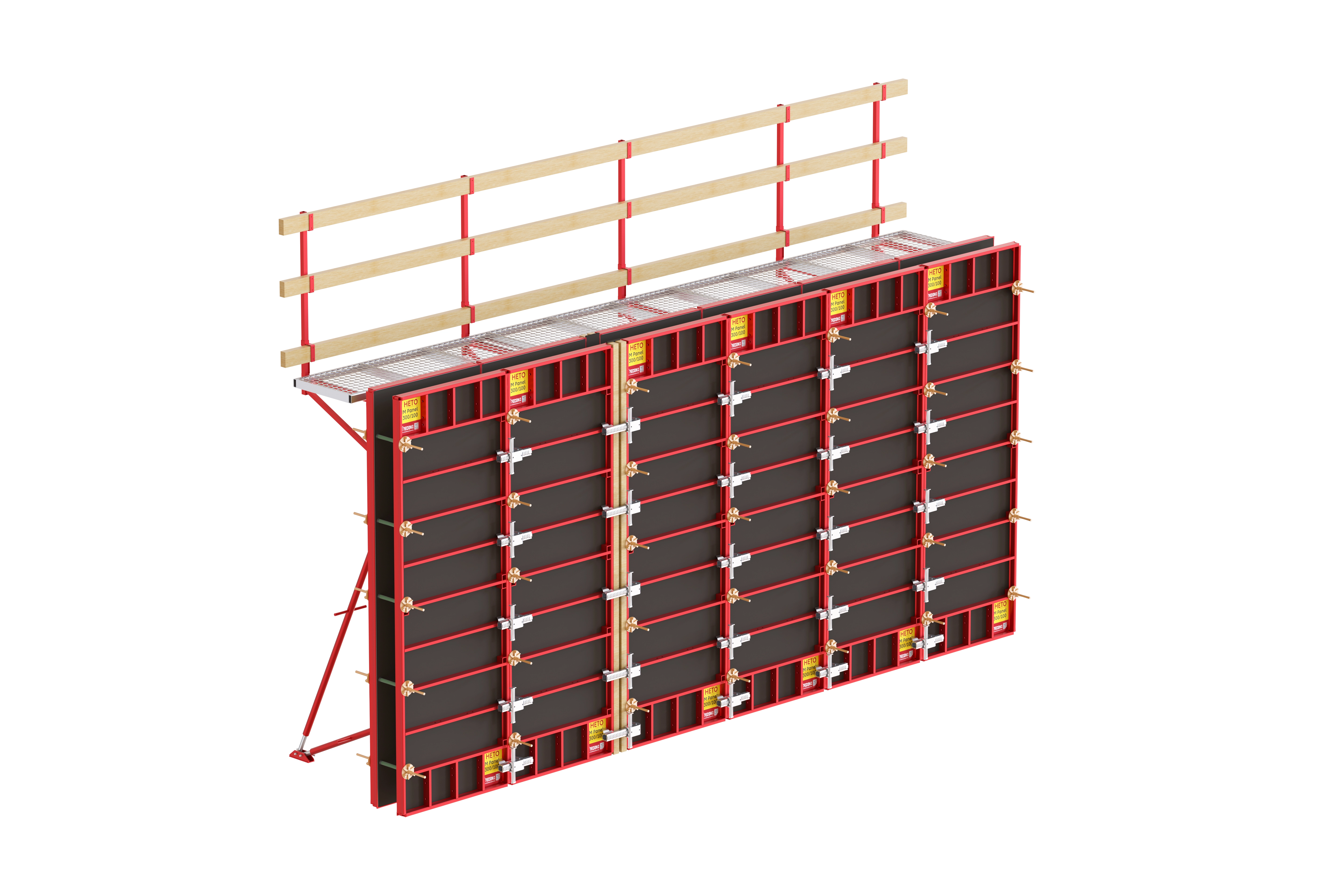

The common problems with wall steel formwork are inconsistent concrete thickness, inaccurate section size, loose joints, and large gaps causing slurry leakage.

The steel formwork should be designed according to the wall height and thickness to determine the sizes and spacing of longitudinal and transverse joists, the support method for the wall, and the form of corner formwork. The upper opening of the steel formwork should have tie rods to prevent oversizing.

Personnel entering the construction site must wear helmets, and those working at heights must be securely connected with safety belts.

When dismantling the cylindrical steel formwork, cooperation and teamwork are necessary, and tools must not be thrown when passing them to others.

The installation and placement of cylindrical steel formwork must be neat and tidy, and materials should be neatly arranged after use.

The lifting and transferring of formwork must be entrusted to specialized personnel and must not be carried out in violation of regulations.

Environmental education should be strengthened for employees before entering the site to improve their environmental awareness.

Mechanical management should be strengthened to reduce noise during construction.

With our professional R&D team and experienced technical team members from our formwork company, we will provide you with on-site assistance when necessary. Our solutions are always cost-effective, and you can be assured that we will support you from the first contact to the completion of the construction. Please feel free to contact us for further inquiries.