Steel formworks, which are one of the types of formworks in construction, are widely used, especially in the north, mainly for cast-in-place reinforced concrete engineering. Large templates for beams, columns, walls, and floor slabs should be assembled according to the design requirements before use. They can be hoisted and moved as a whole or disassembled and transported separately, which is convenient for construction. They are easy to use, highly versatile, easy to assemble, and can be used multiple times. However, they require significant investment and have many joints, making them prone to deformation. After disassembling, plastering is generally required, and some also require chiseling.

Regarding the removal of steel formworks, it has always been a concern for many customers. We would like to tell you the safety measures for disassembling irregular-shaped steel formworks:

It is strictly forbidden to use a sledgehammer and a crowbar to smash and pry the steel formwork during the disassembly process, as this can damage the template.

During the disassembly of steel formworks, workers should stand in a safe place. After the section of steel formwork is completely disassembled, the template, accessories, and supports can be transported out and stacked, generally non-load-bearing templates first, then load-bearing templates, side panels before bottom panels. The disassembly sequence of the frame structure steel formwork is generally as follows: column, beam side panel, cast-in-place slab, beam bottom panel, and disassembled template.

Steel formwork accessories are strictly prohibited from being thrown away. They should be stacked in designated locations and cleaned and maintained in a timely manner. After use, they should be coated with an isolation agent to prevent rust.

Steel formwork products can be laid out and arranged according to different usage environments and special performance requirements. By selecting suitable raw materials and laying methods and arranging procedures according to the product design, the material and structure can be completed in one-time, avoiding the secondary processing usually required for metal materials. This greatly reduces the material consumption of the product and reduces human and material waste.

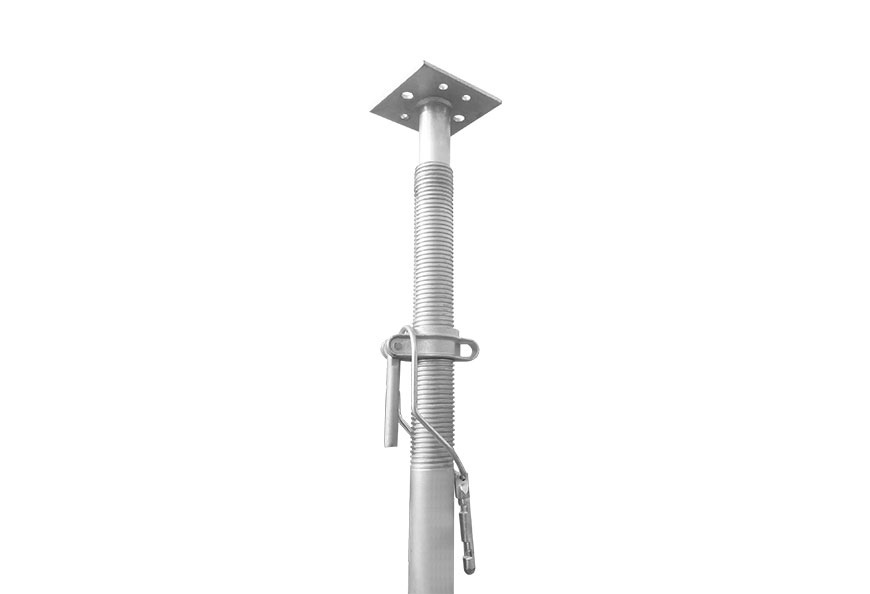

The positive and negative tight screw rods are supported by shear wall templates and composed of adjustable vertical beams consisting of outer sleeves, beam cores, and live joints. The outer sleeve has two layers of live joints, one side of which is welded with a fixed piece connected to the template, which can be connected to the template with round nails.

The beam core of the steel formwork can slide freely in the outer sleeve and live joint to ensure the working length and support quality of the vertical beam. The outer sleeve and live joint of the horizontal beam are made of cold-rolled steel with a thickness of 2mm and welded together.

The exterior of the steel formwork is smooth, and the cross seams are tightly closed to prevent spillage of the mortar. The size of the outer mold for the column template can be adjusted according to customer requirements. When using concrete, it can achieve the effect of clear water concrete, making it easy to demould.

With our professional R&D team and experienced technical team members from our formwork company, we will provide you with help on-site when necessary. Our solutions always have cost-effectiveness, and you can rest assured that we are always there to support you, from the first contact to the completion of the construction. Welcome to inquire.