Most buildings in the infrastructure industry require bridge formworks. Workers must pay attention to the following points when using bridge formworks during construction:

Quality re-inspection of bridge formworks

Before using bridge formworks, the quality supervision department organizes re-inspection and validates the backup templates before they can be used again.

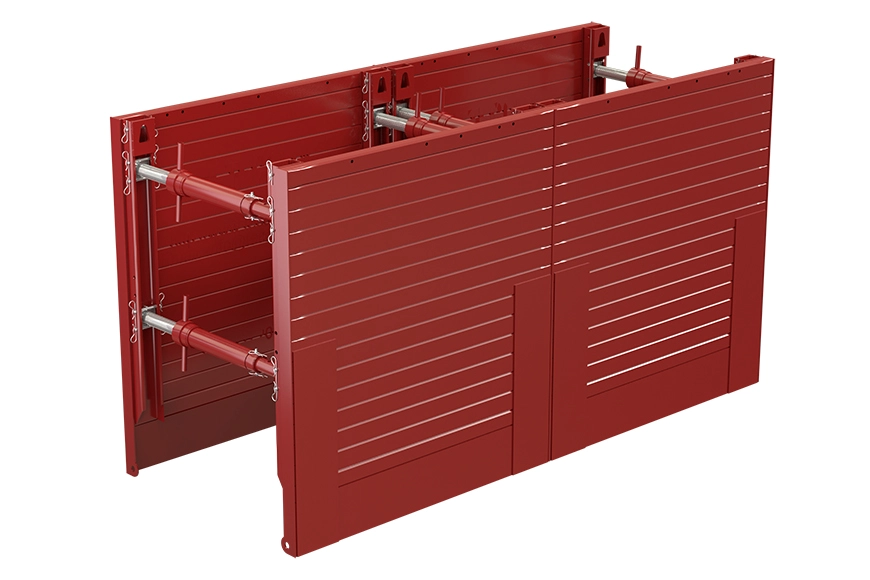

Ensure the strength and stability of the bridge formwork

bridge formworks should be assembled with 2mx1.5m steel templates, which have sufficient strength, rigidity, and stability to withstand the possible gravity, lateral pressure, and various loads during pouring and construction of concrete, and adopt 50 steel pipes as the horizontal and vertical reinforcements of the template.

Attention to covering the bridge formwork

After the template is laid, it must be covered before pouring concrete to prevent the board surface from cracking due to exposure to the sun.

Thickness of the protection layer of the bridge formwork

Inside the bridge formwork, one of the types of formwork systems, place precast concrete pads with the same label between the reinforced steel and the template on the cover plate to ensure the thickness of the protection layer.

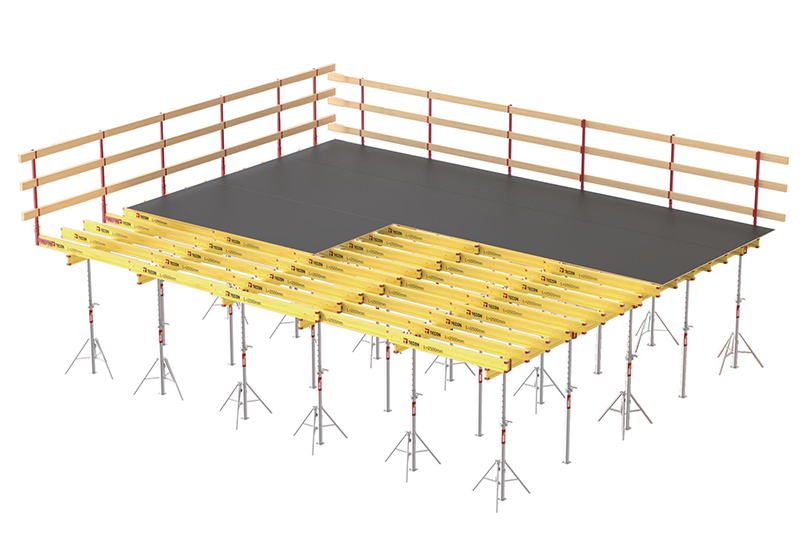

The position of the bridge formwork must be accurate

The outer side is fixed with pressed steel or square wood on the foundation pit wall to ensure that the position is correct. 50 steel pipes are used to build scaffolding around the template, which is convenient for template installation and concrete pouring.

Use release agents and clean the bridge formwork

Release agents must be applied before each use, and the board surface should be cleaned promptly after use. Knocking or scraping the surface of the scraper is strictly prohibited.

Entry time of the bridge formwork

The bridge formwork should be inspected before and during concrete pouring.

Special inspectors implement quality supervision

Dedicated inspection personnel from the safety and quality supervision department are responsible for the quality supervision of the installation and removal of the bridge formwork during use.

Check whether there are debris inside the bridge formwork

Before pouring concrete, check whether there are debris inside the bridge formwork, and whether there are gaps, holes, etc. between the templates. If so, remove the debris inside the template promptly.

Light handling of the bridge formwork

Bridge formworks should be lifted and placed lightly during handling to prevent damage or deformation caused by collisions.

Anti-rust treatment of the bridge formwork

Bridge formworks that are not in use for a long time should be stored in the warehouse. Bridge formworks that cannot be stored should be covered with tarpaulins or other protective facilities, and anti-rust treatment should be performed.

Strictly follow the drawings when using the bridge formwork

The operator should strictly follow the drawings and operating procedures, do self-inspection and mutual inspection during the installation process, to ensure the installation accuracy of the bridge formwork and the normal use of the bridge formwork.

Brush release agent on the bridge formwork

After the bridge formwork is released, thoroughly remove any remaining concrete and apply a release agent evenly.

Storage by classification

Each production department is responsible for the storage of the bridge formwork. The warehouse should be divided into zones, categories, and neatly stacked. The storage area should be solid and flat to prevent corrosion and deformation during storage, and avoid long-term outdoor stacking. Only by strictly following the construction requirements and using methods of building templates can enterprises ensure the quality and safety of the project.

As one of the leading experts in the field of formwork and scaffolding projects, our wide range of off-the-shelf and custom products ensure that we can provide solutions for your building project, no matter how large or small or wherever it is located. Please feel free to contact us for any inquiries.