As we all know, building formwork plays a pivotal role in the process of engineering construction, because it can effectively ensure the safety of construction, so what should we pay attention to in the process of demolding of building formwork?

The demolition of the building formwork shall be based on the compressive strength report of the concrete test block under the same conditions, and then the application form for demolition shall be filled in, signed by the professional foreman and the project technical person, and submitted to the supervisor for approval before it becomes effective.

Side form: The side form can be removed only after the concrete strength can ensure that the surface edges and corners are not damaged due to the removal of the building formwork.

Bottom form: The bottom form can only be removed after the concrete strength of the component with a span greater than 8m reaches 100% of the design strength. The bottom form can be removed only after the strength of the concrete with a span of less than 8m reaches 75% of the design strength. The dismantling of the pre-stressed part is to be demolished after the concrete strength and pre-stress required by the design are reached.

The order of dismantling the building formwork is opposite to the order of installation. The order of installation is to support first and then to dismantle, and the order of formwork removal is to dismantle after support. That is, the non-load-bearing building formwork is removed first, and the load-bearing building formwork is removed later. The vertical wall construction formwork is removed first, and the horizontal wall construction formwork is removed later. The outer wall construction formwork is removed first, and the inner wall construction formwork is removed later.

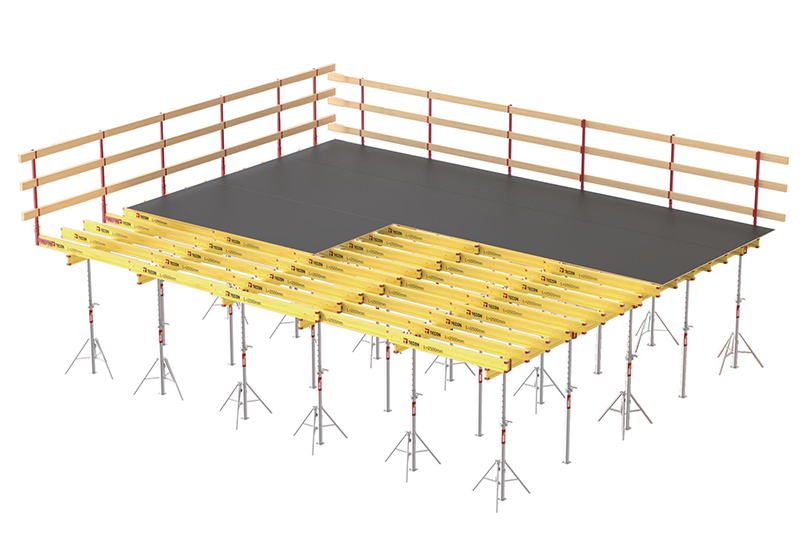

(1)Removal of beam slab: first loosen the upper adjustable support of the support to separate the keel from the building formwork, and lower the keel to the horizontal tie rod, and then remove all the attachments of the building formwork on the side. Then use the iron drill to move the building formwork, so that the building formwork is lowered and supported by the keel, and the building formwork and the keel are removed.

(2)The beam and column molds can be removed only when the surface is not damaged. First, remove the diagonal brace, then remove the building formwork and the opposite bolts and accessories, and then gently pry the building formwork with a crowbar to separate it from the concrete.

(3)When removing the building formwork, clean up the adhesive in time, apply the release agent, and stack it neatly. The dismantled components shall be managed in a centralized and unified manner in time, and corresponding protective treatment shall be applied.

(4) When removing the building formwork, the operator should stand in a safe place. When removing the lower support of the beam with a larger span, start from the middle of the span and remove it to both ends.

(1) Before dismantling, check whether the fastener connections of the support system and the support system meet the safety requirements.

(2) Remove the debris and obstacles on the ground before removing the support.

(3) Demolition should be carried out layer by layer from top to bottom, and simultaneous top and bottom operations are strictly prohibited. The horizontal rod should be removed layer by layer following the vertical rod.

(1) Before installing the roof frame and building formwork, the team should make a comprehensive technical safety report, and make a detailed technical report on the installation method, installation sequence, technical standards, quality and safety requirements, etc.

(2) During the installation of the roof, temporary measures to prevent overturning should be provided, and it should be fixed after installation and verification of correctness.