As we all know, aluminum alloy formwork is the most used turnover material in construction projects. At present, wood formwork is mostly used. With low carbon and energy saving, more and more attention is paid to the society. Utilization is a widely thought and urgent problem to be solved.

People turn their attention to aluminum alloy formwork, such as all-steel formwork, etc. Aluminum alloy formwork solves the loss of wood and speeds up the construction speed to a certain extent, but all-steel formwork is self-important, relies heavily on vertical transportation system, and is not easy to operate. Disadvantages such as convenience affect the scope of its promotion.

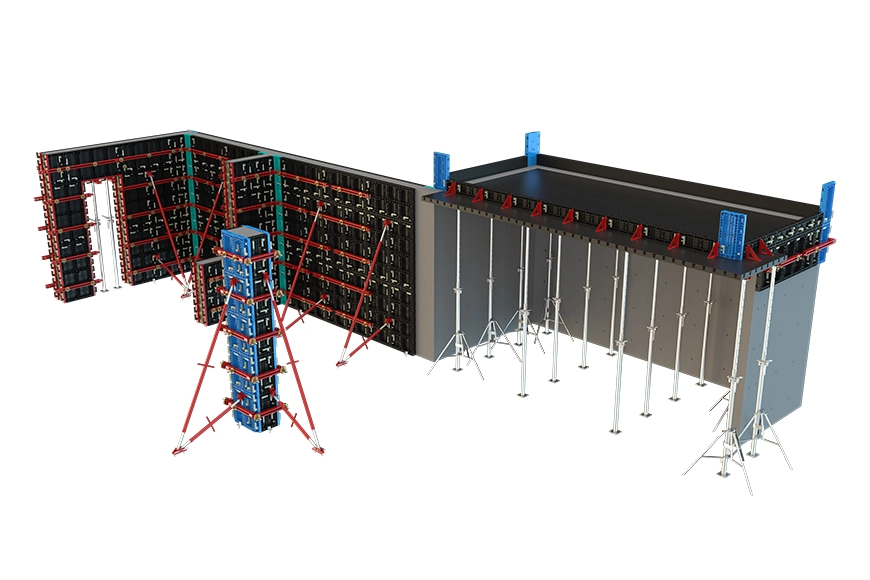

The appearance of aluminium formwork has solved this problem very well. It has light weight, convenient assembly and turnover, and good structural forming effect. It has been successfully promoted in foreign countries, such as the United States and Canada, for 10 years, and also in Hong Kong and Macau, China. has been widely used.

The aluminum alloy formwork is deepened and matched by the factory according to the construction drawing, and is made of aluminium formwork and aluminum alloy profiles.

The concrete surface quality is good after the aluminum alloy formwork is removed. According to this construction method, the formwork can be installed flat and firm, and the concrete surface can achieve the effect of fair-faced concrete.

Aluminum alloy formwork has high technical content, strong practicability, and many turnover times (theoretically it can reach 300 times), which can significantly reduce the cost of engineering formwork and shorten the construction period of the project; the economic and social benefits are significant, and it has broad application prospects.

The components of the aluminum alloy formwork system need to be designed according to the characteristics of the floor, which requires high computer software and designer capabilities. About 80 of the modules in the complete aluminum alloy formwork system of the aluminium formwork manufacturer can be recycled in multiple projects, while the remaining 20 can only be recycled in one class of standard floors. Therefore, the aluminum alloy formwork system is suitable for standardized high-rise buildings or multi-storey buildings and villas. In areas with a high degree of urbanization, the following technical advantages can be reflected:

1. The construction period of aluminum alloy formwork manufacturers is short. The aluminum alloy building formwork system is a quick-release formwork system. The normal construction of a set of formwork can reach one floor in four days (one set of plates and three to six sets of support systems), and it can be well developed for assembly line construction, which greatly speeds up the construction progress and saves money. management costs.

2. The number of repeated uses is large, and the average cost of use is low. The aluminum alloy building aluminium formwork system adopts the aluminum alloy profile formed by the overall extrusion as the raw material, and a set of formwork standard construction can be turned over and used more than 300 times.