As a new type of formwork system, aluminum alloy formwork system has been applied for nearly 60 years since it was born in the United States in 1962. It has been widely used in the buildings of developed countries such as the United States and Canada, as well as newly industrialized countries such as Mexico, Brazil, Malaysia, South Korea, and India.

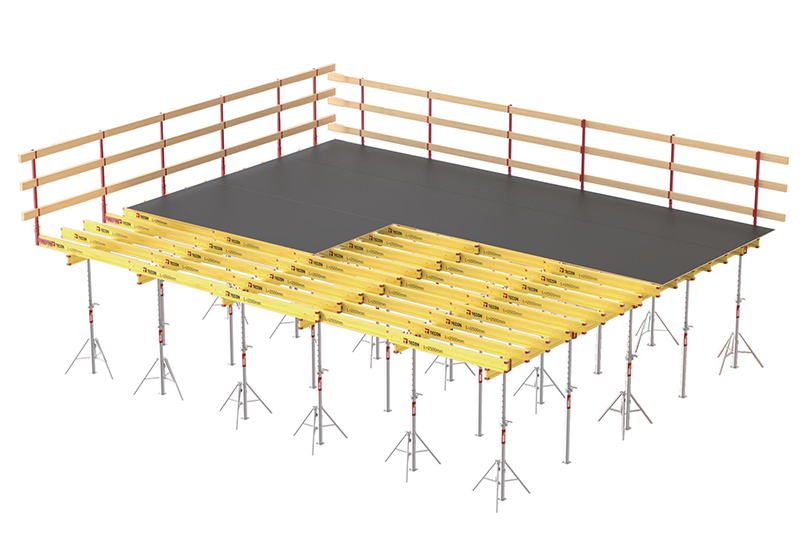

Aluminum alloy formwork system is a new generation of green formwork technology. It is mainly composed of formwork system, support system, fastening system, accessory system and so on. It can be widely used in various fields of reinforced concrete building structures. The aluminum alloy formwork system has the advantages of light weight, convenient disassembly and assembly, high rigidity, large board surface, less joints, good stability, high precision, smooth and clean poured concrete, long service life, high turnover, good economy, and recycling value. It has the characteristics of high construction speed, fast construction progress, high construction efficiency, clean construction site, good construction image, low degree of dependence on machinery, and wide application range.

In recent years, China's coastal provinces and cities as well as Hong Kong, Macao and Taiwan have gradually begun to promote the use of aluminum alloy formwork systems, and have achieved considerable economic and social benefits.

Aluminum alloy formwork is the most ideal tool formwork at present. Aluminum alloy formwork system has been maturely applied in high-rise and high-rise residential buildings, high-rise and high-rise commercial buildings. After the aluminum alloy formwork is used for construction, the wall does not need to be plastered, and the floor thickness, ceiling levelness, verticality, flatness and other indicators can be improved to a level close to 100% qualified; after using the aluminum formwork, no plastering is required. , After the surface of the concrete wall column is cleaned and cleaned, the decoration construction can be directly carried out after partial treatment.

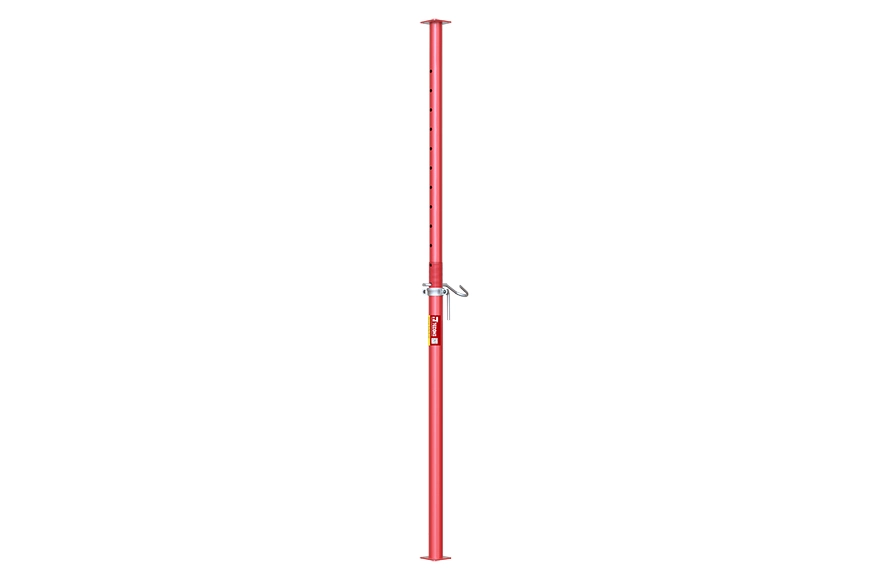

This aluminum template is an aluminum alloy template. The aluminum alloy formwork is composed of four partial systems: the formwork system, the fastening system, the support system and the accessory system. It has a complete formwork system and is suitable for formwork systems of different structures. The aluminum alloy formwork is divided into flat formwork and corner formwork according to the structure. and components. Among them, the corner formwork includes an external corner formwork, an internal corner formwork and an internal corner formwork, and the components include a single inclined aluminum beam, a double inclined aluminum beam, a floor slab early dismantling head, and a beam bottom early dismantling head.

Non-rectangular formwork and non-conventional components are not included in the identification scope of the above-mentioned standard parts and non-standard parts. Aluminum alloy formwork development and editing. All-aluminum alloy formwork technology originated in the United States in the 1950s, and has been implemented in developed countries such as the United States and Canada. It has gradually been used in the construction field of Asian countries such as Malaysia, South Korea, Japan, India, etc., from Mexico and Brazil, and has been widely used in the subsequent development, mostly used in the construction of high-rise residential buildings.

The design, development and construction application of aluminum formwork is a major development in the construction industry. The application of aluminum alloy formwork system in the construction industry has improved the construction efficiency of housing construction projects, including saving a lot in building materials and labor arrangements.