The construction of aluminum formwork is a particularly troublesome task, because for a large or super large construction project, it is not sufficient to just have the entire concrete frame completed to meet the requirements. The function of a large construction project is an essential part of the construction process. Among them, the embedded parts in the construction of aluminum formwork are a manifestation of the building's functions.

In the entire construction process, it is important to control the pace of construction and do it in an orderly manner, even if it is quite difficult. Aluminum formwork manufacturers also suggest making a comprehensive planning before construction. In addition to harmonizing with each unit participating in the construction, the more important part is the transportation and operation of construction equipment and materials.

Aluminum formwork system is an important construction tool and the basis for construction. Of course, the risks of engineering projects still need to be considered, including delays in work due to various factors, worker issues, adequate materials and construction risks, etc. All the problems that may arise during construction need to be taken into consideration. After all, a large project still requires a rigorous and feasible construction plan. Although unexpected situations may disrupt the plan, without a plan, it will be even more chaotic. Therefore, every step must be done well to ensure smooth construction.

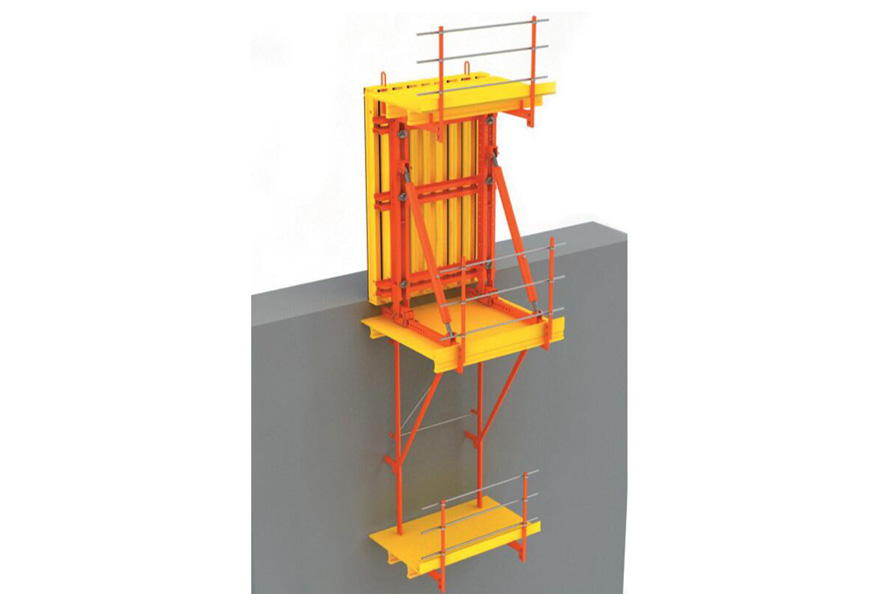

The support system of the aluminum alloy formwork should be arranged according to the load of the formwork and the stiffness of the components. The equipment direction of the steel back rib should be perpendicular to the length direction of the formwork, directly bearing the load transmitted by the formwork, and the distance should be calculated according to the value of the load and the mechanical properties of the formwork.

The deflection of the end of the overhanging part of the steel back rib should be roughly the same as the deflection in the middle, and the overhang length should not be greater than 50mm.

For columns and beams with larger cross-sections, pull bolts and steel back ribs should be used.

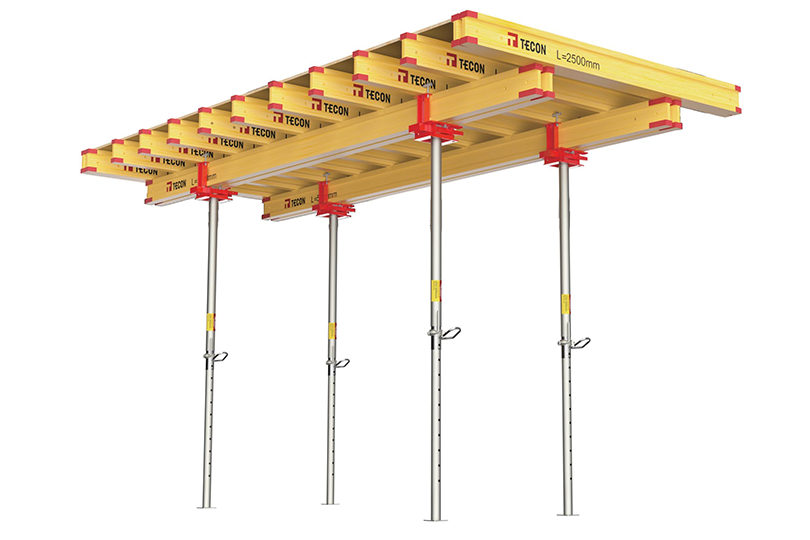

When the end seams of the formwork are arranged flat, there should be two support points for each aluminum alloy formwork. When staggered, the distance should not be constrained by the direction of the end seams.

When the clear height of the formwork bottom is not greater than 3.10 meters, a single support top without a horizontal linkage can be used as a support.

The single support head is designed with an external diameter of Φ60×2.5 steel pipe and an internal diameter of Φ48×2.0 steel pipe.

As one of the leading experts in the field of formwork and scaffolding engineering, our extensive range of ready-made and custom products ensure that we can provide solutions to your construction projects, no matter how big or small or where they are located. Feel free to inquire.