Bridge formwork is a commonly seen steel formwork in bridge engineering. Do you know the classification of bridge formwork and its design principles?

Classified by structure types

Different shapes, sizes, and structures of various cast-in-place reinforced concrete structural components form different characteristics of bridge formwork and assembly methods.

According to the structural forms, including various types of formwork systems, it can be classified into foundation wall formwork, pier column formwork, bridge deck (beam) formwork, parapet formwork, tunnel formwork, etc.

Classified by construction methods

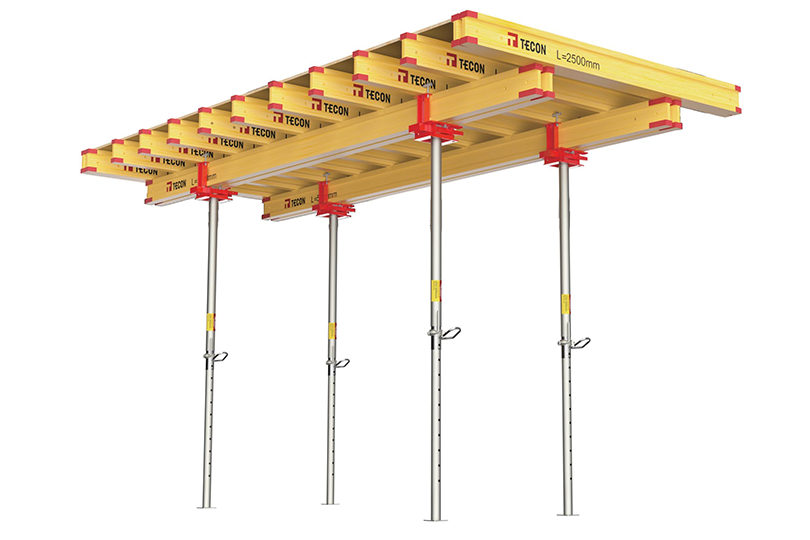

Bridge formwork on-site assembly and disassembly: The formwork is assembled at the construction site, which depends on the design requirements of the structural shape, size, and spatial position. The on-site assembly and disassembly of the formwork are mainly supported by the structural formwork and tool types.

Classified by materials

According to the materials used, the bridge formwork can be classified into wooden formwork, steel and wooden composite formwork, plywood formwork, steel bamboo formwork, steel formwork, plastic formwork, fiberglass formwork, and aluminum alloy formwork.

Practicability

To ensure the construction quality of the prefabricated highway beam "T" section, the joint of the bridge formwork should be tight and sealed without leakage. All parts and components should be simple and easy to assemble and disassemble.

Safety and economy

The bridge formwork should have sufficient bearing capacity and rigidity. Through technical and economic comparisons, the one-time investment of bridge formwork can be reduced, and the turnover of bridge formwork can be accelerated while reducing the structural weight of the bridge formwork.

Laying out, cutting, welding single pieces, calibrating, self-inspection, leaving a complete prefabricated assembly, checking the shape and size, final acceptance, anti-corrosion treatment before leaving the factory. According to the position, shape, and size of various parts of the prefabricated highway "T" section component on the dam top and their mutual relationship, the configuration of the bridge formwork should be reasonably planned while considering the operating conditions of tying steel bars and pouring concrete to facilitate construction.

When designing bridge formwork, its strength and stability should meet the requirements, and special construction requirements should be taken into consideration in the structure. In order to save materials and reuse the bottom module pedestal, the pedestal construction uses concrete, and the local flatness of the pedestal surface is controlled within 2mm. Steel pipes are pre-embedded at 500mm intervals to form tie rod holes under the bridge formwork. Angle steel is used to control the receiving elevation on both sides of the bottom module to form a 20mm arch curvature. The steel plate base is anchored to the concrete floor slab with M12 expansion bolts.

With the professional R&D team and experienced technical team members from our formwork company, we will provide you with assistance on site when necessary, and you can rest assured that our solutions are always cost-effective. From the first contact to the completion of construction, we will always be there to support you. Welcome to inquire.