1. The joints of the building formwork should be tight to reduce the voids in the core of the building formwork and increase the pressure-bearing capacity of the building formwork.

2. Ensure that the dimensions and mutual positions of each part of the concrete structure and components are accurate. The plane position, elevation, shape and cross-sectional dimensions of the building formwork conform to the requirements of the design drawings. Ensure that the position mentioned above, elevation, shape, and cross-sectional dimensions do not exceed the allowable range during and after the concrete is poured.

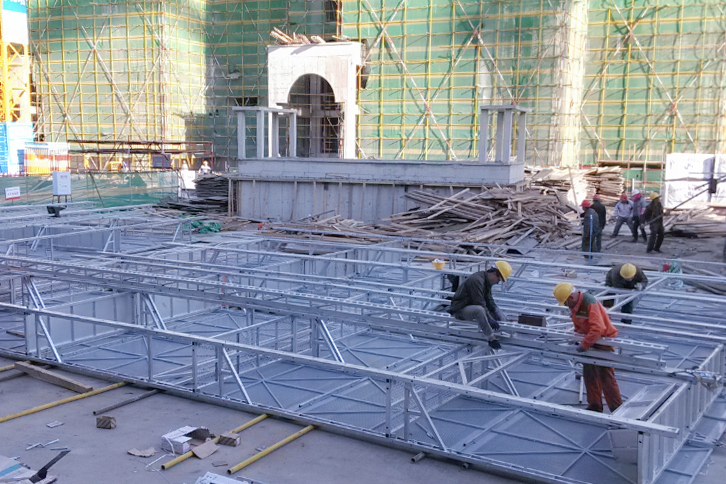

3. The construction template is simple in structure and easy to disassemble and assemble. It is flexible and meets the technological requirements of binding and installing steel bars and concrete pouring and maintenance. The building shuttering has a precise force and is suitable for centralized manufacturing. It is convenient to improve the mechanization and factorization of the building shuttering engineer manufacturing while saving raw materials. It can reduce labour intensity, improve work efficiency, speed up construction progress, and meet the process requirements of subsequent procedures.

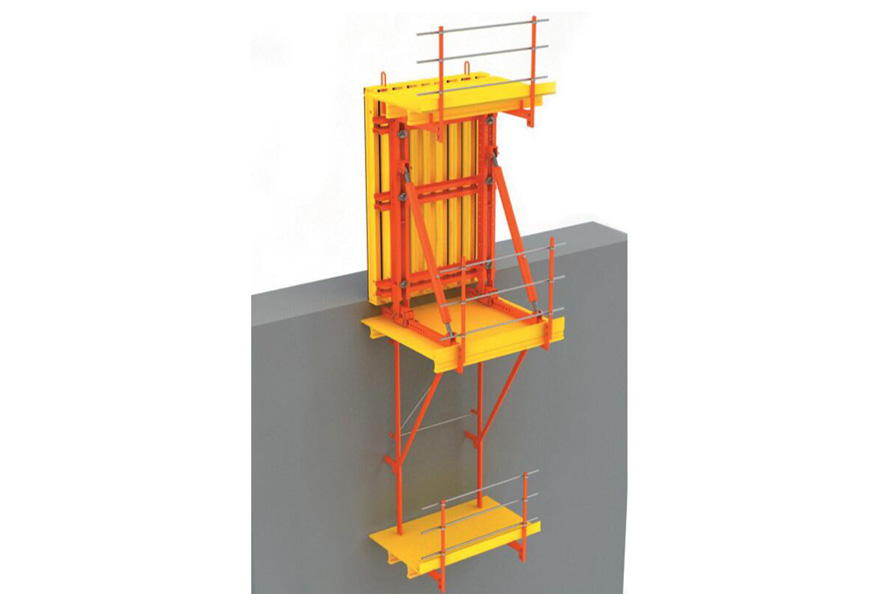

4. The building shuttering can reliably bear all the loads generated during construction and has sufficient strength, rigidity and stability. It can reliably bear the weight and lateral pressure of the newly poured concrete and the load generated during the construction process. That is, it is required that the building formwork project can withstand various loads that may occur during normal construction and everyday use.

In the process of pouring concrete and its curing, the following bearing capacity limit states should not appear, such as the entire structure or part of the component loses balance; the structural component or connection is damaged due to insufficient material strength, or excessive plastic deformation; the structure is transformed into a mobile system, and the structure or component loses its stability.

In the construction industry, the choice of building materials is very critical. As long as there are subtle differences, the project will fail. Therefore, the normal selection of materials is particularly important. We will introduce you to the correct choice of building formwork manufacturers.

The wall formwork can be selected from a medium-sized composite building template manufacturer. Since the general requirements of the same high-rise building group are uniform, the medium-sized composite building template manufacturer helps ensure a higher turnover rate.

It is recommended to use the whole multilayer board for the floor building template and choose the 15~18mm thick multilayer building template manufacturer with phenolic cladding. The edge of this building template is damaged after repeated use, so it must be cut in time to ensure that the edge of the multilayer board is flat.

The construction of beam-column houses should adopt medium-sized composite building template manufacturers. Because of the large changes in the cross-section of beams and columns, it is not suitable to use multilayer board cutting.