1. Features

(1) Hollow plastic formwork has good workability, which is the same as the construction method of wooden formwork;

(2) No moisture absorption, corrosion resistance, acid and alkali resistance, especially suitable for use in humid environments;

(3) High strength, impact resistance, abrasion resistance, long service life, turnover usage times can reach more than 50 times;

(4) The surface is smooth, smooth, no need to brush release agent, can be sawed, can be nailed;5. The used waste boards and scraps can be recycled and reused, saving costs and reducing pollution.

2. Instructions

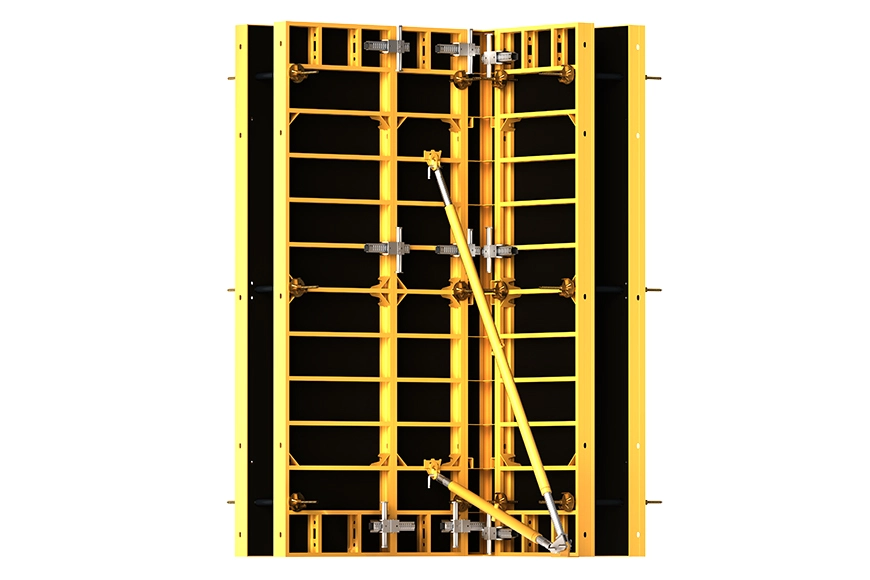

(1) Like the wooden formwork, the vertical rib direction of the hollow plastic formwork forms a cross with the direction of the woodside;

(2) No need to apply mold release agent before use;

(3) When the slab is cast in place, the keel spacing is 20~25cm, and the keel spacing of the slab wall is 15~20cm;

(4) The splicing seam between the board and the board needs to be sealed with tape;

(5) The nail length should not be too long, generally about 30~35mm;

(6) The nail strength should be moderate;

(7) When disassembling the hollow plastic formwork, it is necessary to remove the hollow plastic formwork from the small piece at one end while removing the support to prevent the large area from falling, and do not let the corners fall vertically against the ground;

(8) Hollow plastic formwork can be mixed with templates of wood plywood, bamboo plywood, and other materials.

1. Green and environmentally friendly, no pollution The hollow plastic formwork is made of high-quality imported engineering polypropylene. The product is green and environmentally friendly and has no pollution, lightweight, high hardness, impact resistance, abrasion resistance, smooth and clean surface, and good casting effect.

2. It can be used 50 times in turnoverHollow plastic formwork does not damp, deform, mildew. It is well resistant to acid and alkali corrosion. soaking it in water for a long time will cause no delamination and foaming. The sheet size is stable, good toughness, long service life, normal use can be turned around 50 times.

3. Easy demoulding can shorten the construction periodThe hollow plastic formwork is easy to demold and does not need to use a mold release agent. It can effectively shorten the construction period, save labor, and the product is easy to process. It can be ordered, sawed, drilled, and can be spliced horizontally and vertically.

4. The product can be recycled or traded in hollow plastic formwork products can be 100% recycled and reprocessed or replaced with new ones in the later stage, effectively reducing the cost of the user and reducing the project cost.

As one of the leading experts in the field of formwork and scaffolding engineering, our wide range of ready-made and customized products ensure that we can provide solutions for your construction projects, regardless of their scale or location. With the expertise of our R&D team, our technical team members will provide you with on-site assistance when necessary, and know that our solutions are always cost-effective. You can be sure that from the first contact to the completion of the construction, we are always there support you.