As the latest hot word in the construction industry, the underground integrated pipe gallery has attracted attention because it not only represents an innovative concept but also brings more new difficulties and challenges to the construction industry. Plastic formwork, as the new generation of innovation protagonists of "plastics to replace steel and plastics to wood", will greatly promote the innovation and development of underground integrated pipe corridors. So in the existing construction practice, what innovative applications have been made of plastic formwork in the construction of an underground comprehensive pipe gallery?

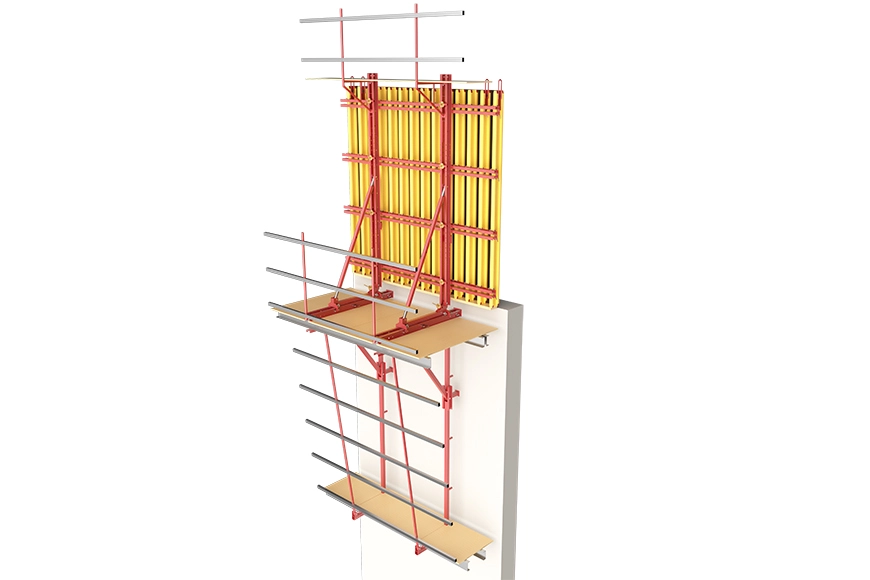

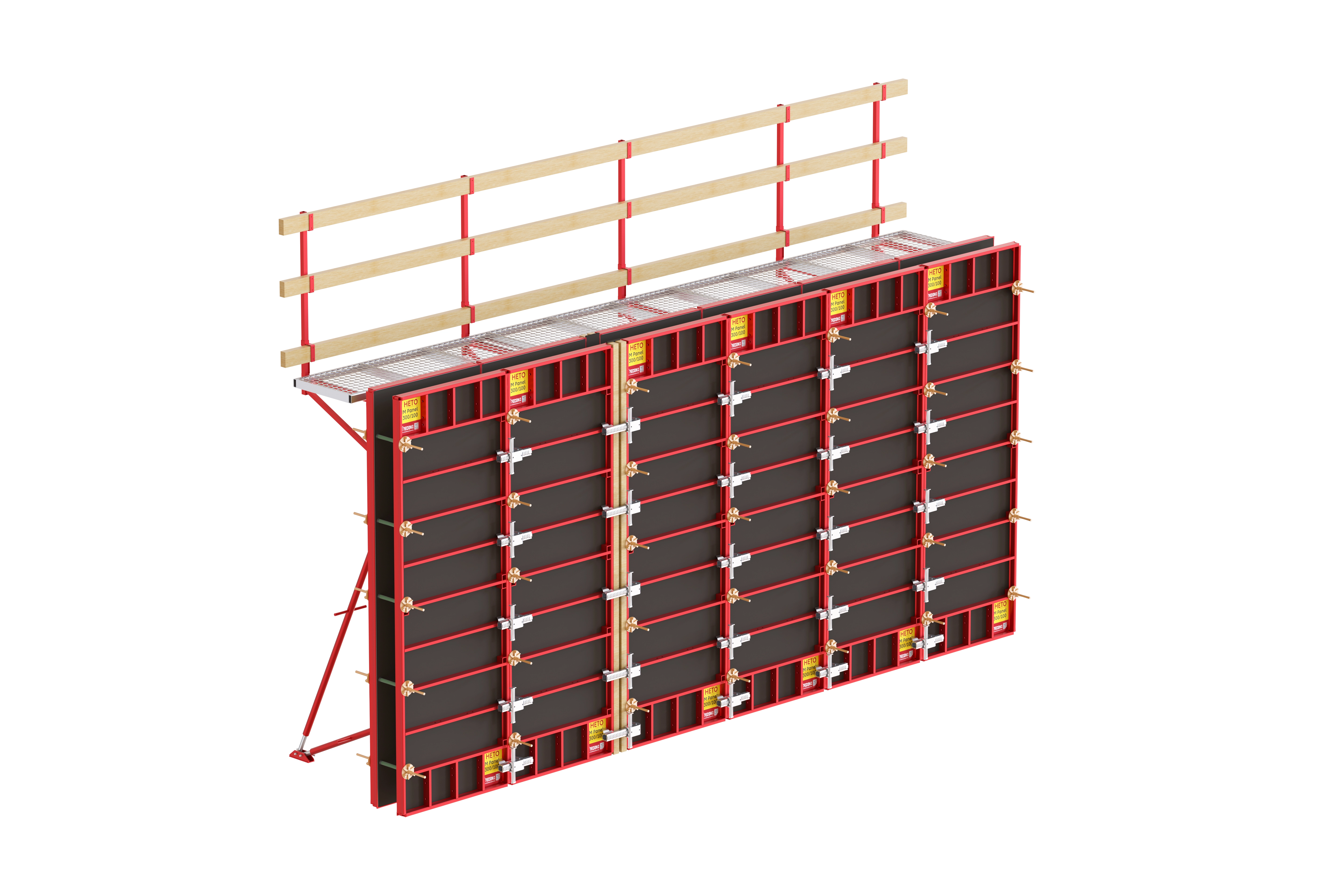

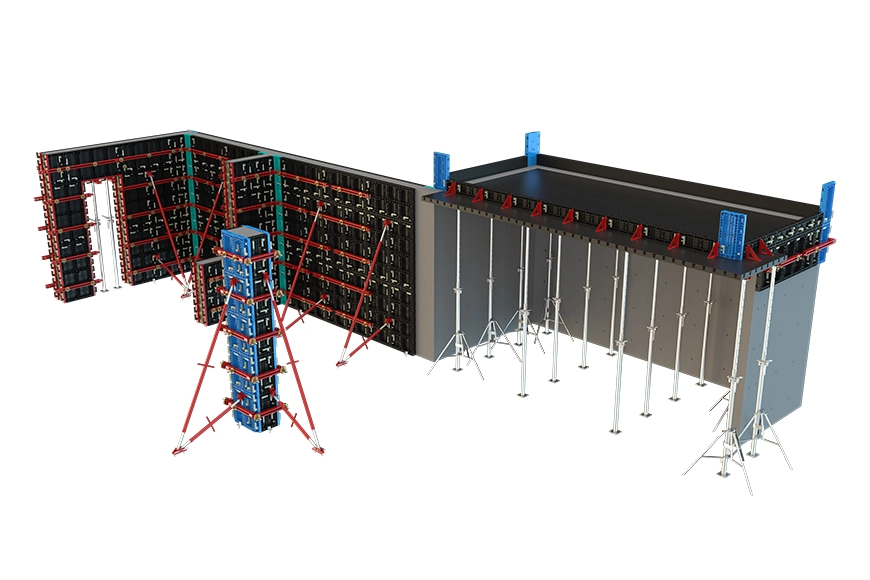

1. Use of stand mold with a movable scaffolding system

The construction environment of the underground comprehensive pipe gallery is usually humid and the construction space is narrow. The use of steel molds and aluminum molds will not only cause rusting of the formwork due to moisture, and then cause performance changes, but also due to excessive weight slowing down the work efficiency, the lighter wooden formwork is also easy to absorb water, swelling and deforming in the underground environment, which cannot meet the requirements of use. The plastic formwork has the outstanding features of lightweight, high-temperature resistance, corrosion resistance, water resistance, and high turnover rate, which just solve the above difficulties.

2. Irreplaceable environmental advantages

Plastic formwork has a large application space in the field of underground comprehensive pipe corridors, which is reflected in not only effectively improving construction efficiency, but also the environmental protection advantage of plastic formwork for recycling. In contrast, steel molds and aluminum molds are non-renewable, and wooden molds are harmful to the ecology, while plastic formwork is environmentally friendly. Therefore, many large and responsible enterprises have begun to use plastic formworks.

The savvy hears when the environment is silent, the wise see things before it formed. The use of plastic formworks is the trend of the times. Suzhou TECON Construction Technology Co., Ltd has always been committed to providing customers with more diversified plastic building materials products with better comprehensive benefits, and creating value for customers!