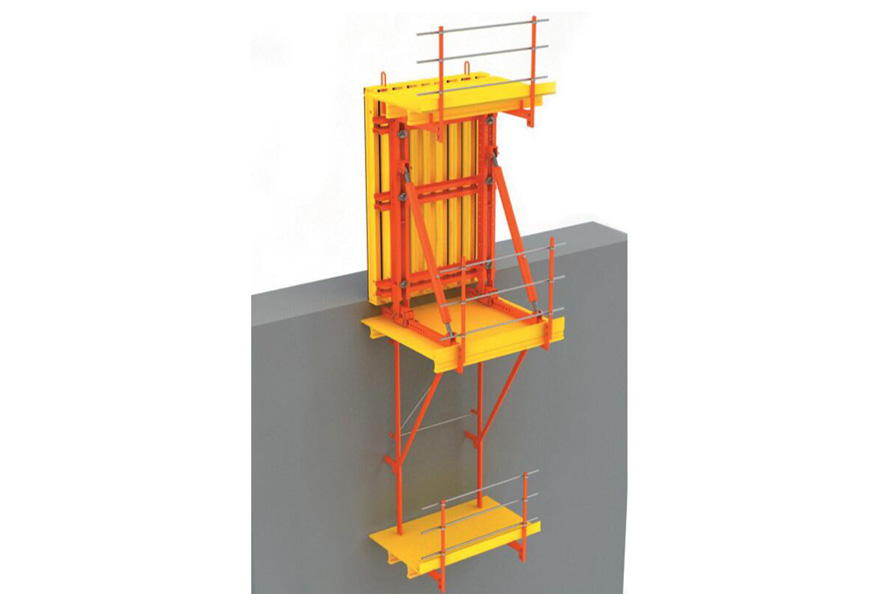

The bridge formwork is suitable for construction sites with limited access, such as deep valleys, rapids, highway and railway interchanges, scenic spots, and nature reserves. The bridge rotation construction relies on the rotation of the structure itself to be in place, without the need for lifting equipment, which can save support wood or pier template and is one of the main types of bridge formworks. The pier template adopts a perforated tension rod structure. The steel template is composed of panels, longitudinal and transverse ribs, and back ribs. Its strength, rigidity, and stability should meet the construction requirements.

1) Before assembling the pier template, it should be polished flat, and the joints should be flat and the inner surface of the template should be free of rust;

2) The template is connected layer by layer on the ground, and the joints are bonded and polished with steel plates. The template is a shaped steel template. Before installation, check the structural size, strength, rigidity, and surface flatness. Then accurately release the outer contour line of the structure, accurately level the foundation, control the leveling error within 2mm, and ensure that the verticality of the assembled adjustable formwork for the bridge meets the requirements. The release agent should be applied before assembly. After each tower crane is installed, check the verticality of the template and the upper template, and manually assemble the template. After each layer of the template is erected, tighten each steel bar bolt one by one, and lift the template with a lifting spreader, from bottom to top, and install it to the top of the pier in sections.

3) After each set of templates is installed, the bolts should be immediately tightened, and elastic adjustable cable wind ropes should be installed and tied to the four corners of the top of the template (the inclination angle of the cable wind rope is about 45°), adjust the position, verticality, and elevation of the template, and measure the position and elevation again. In addition to checking the elevation, also carefully check the coordinates of the bridge pier and abutment. The template adopts a combination of steel templates and snap-on steel pipe scaffolding. The template support should be accurate, firm, and there should be no walking or deformation during concrete pouring. The working platform should be supported in a circular arrangement with bowl buckles and should not be connected to the pier and abutment template, reducing the support preloading time of the bridge formwork.

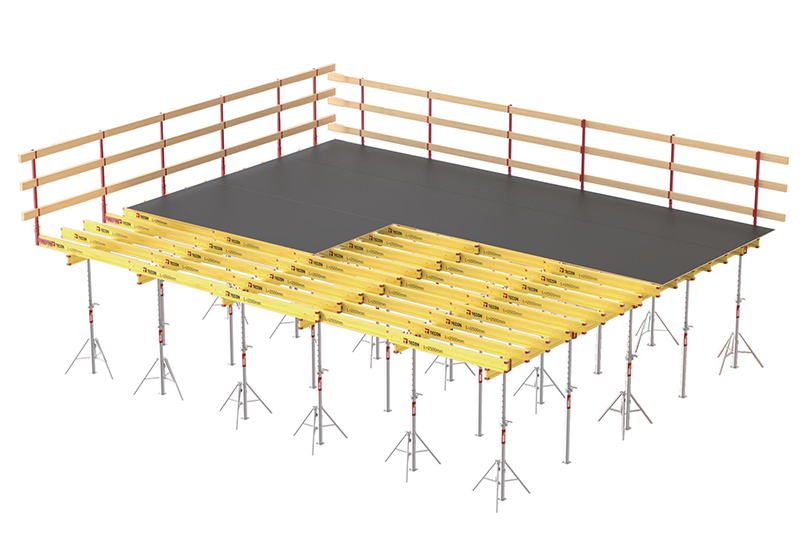

The bridge formwork is particularly suitable for the construction of cast-in-place reinforced concrete projects. After use, the concrete surface is smooth, dense, smooth, and easy to peel off from the concrete surface. The surface is crack-resistant and non-layered, and has strong resistance to common acidic compounds. The design requirements generally require about 7 days. The main control indicators include the cumulative total settlement of the support and the daily settlement. If the daily settlement is basically stable and showing a converging trend, it can be considered that the support is stable.

The specific preloading time can be advanced or extended according to the conditions of the foundation and the development of settlement. The actual control indicators are generally controlled by the settlement of the support. For specific projects, the overall design will provide more specific control indicators in the drawings.

With the professional R&D team and experienced technical team members from our formwork company, we will provide you with assistance on site when necessary, and you can rest assured that our solutions are always cost-effective. From the first contact to the completion of construction, we will always be there to support you. Welcome to inquire.