The aluminum alloy formwork member is the bearing plate that directly contacts the concrete and is the main component of the product system, mainly including plane formwork, corner formwork, aluminum beam, support head, stair formwork and other categories. It is mainly used for concrete pouring and forming of columns, shear walls, structural beams, floors, bay windows, low walls, elevator shafts, etc., connecting the space between the formwork and the formwork.

Aluminum alloy formwork has the advantage of assembly efficiency. First, it is easy to install. The splicing is easy, the density is low, and the average weight is light. The average weight per square meter is only about 25 kilograms. The templates are fixed by pins and pins. The second is quick release. The early dismantling formwork support system is adopted to replace the traditional process of three sets of formwork, so that the concrete can be disassembled in a short time after the completion of the concrete construction. Third, the construction period is short. The doors and windows can be prefabricated in advance, and the doors and windows can be installed after the template is removed. The overall construction period is short; the structural surface achieves the effect of clear water, which can save the plastering and leveling process. .

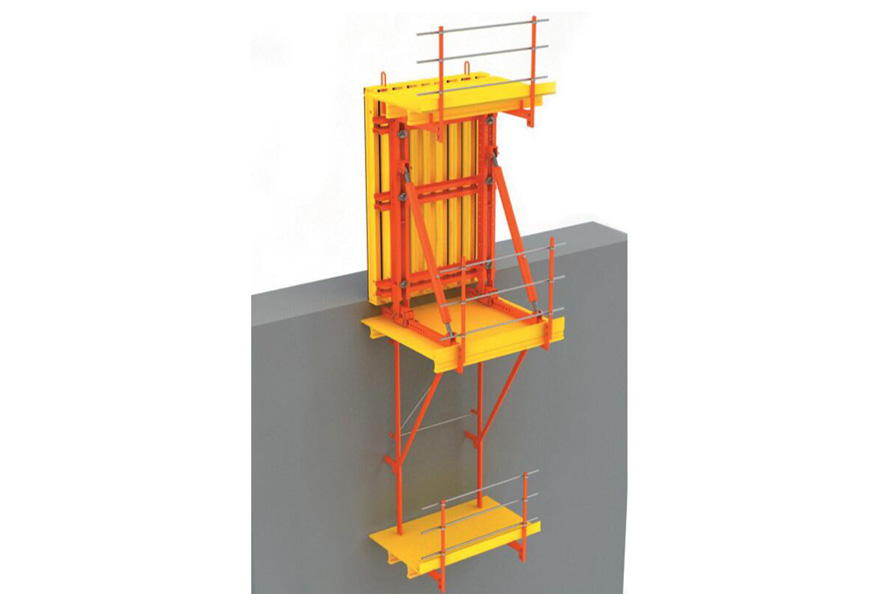

Schematic diagram of the single-layer assembly process of aluminum alloy formwork: each layer is installed, and so on.

Measuring and laying out → wall column reinforcement, positioning reinforcement and water and electricity installation → wall body aluminum composite formwork installation → beam and floor aluminum composite formwork installation → beam building reinforcement and water and electricity installation → concrete overall pouring → wall formwork removal → beam plate formwork removal (Do not dismantle the top of the single support) → install the next layer.

What should be paid attention to when dismantling aluminium formwork? Before dismantling, a working platform should be erected to ensure stability; when the formwork is dismantled, the strength of the concrete must reach the design allowable value; when dismantling the formwork, do not loosen or collide with the support rod; when the formwork is dismantled, the dirt on the formwork should be cleaned immediately and brushed in time. Release agent.

1. The aluminium formwork manufacturer removes the side formwork of the wall column

Under normal circumstances, the side formwork of the wall column can be removed 12 hours after the concrete is poured. First remove the diagonal support, and then remove the wall bolt. When removing the wall bolt, use a wrench to loosen the nut, remove the gasket, remove the lower back corrugation, and tap lightly. Remove one end of the bolt until the bolt exits the concrete, then remove the pin connected to the formwork, use a crowbar to pry the formwork to separate the formwork from the wall, clean up the removed formwork and accessories in time, and transport them to the same position on the upper floor and lay them flat.

2. The aluminium formwork manufacturer removes the top form

Under normal circumstances, the top mold can be removed after 48 hours. The removal of the top formwork starts from the position of the beam and the plate support rod, removes the beam and the plate support rod pin and the connecting piece connected to it, and then removes the pin of the adjacent beam and plate, and then the formwork can be removed, and the crowbar can be used to remove the top formwork. The junction between the formwork and the concrete shall be pryed off, and the support rod shall be kept as it is and shall not be loosened when dismantling. The removed templates and accessories should be cleaned up in time, and transported to the same position on the upper floor and stacked flat.