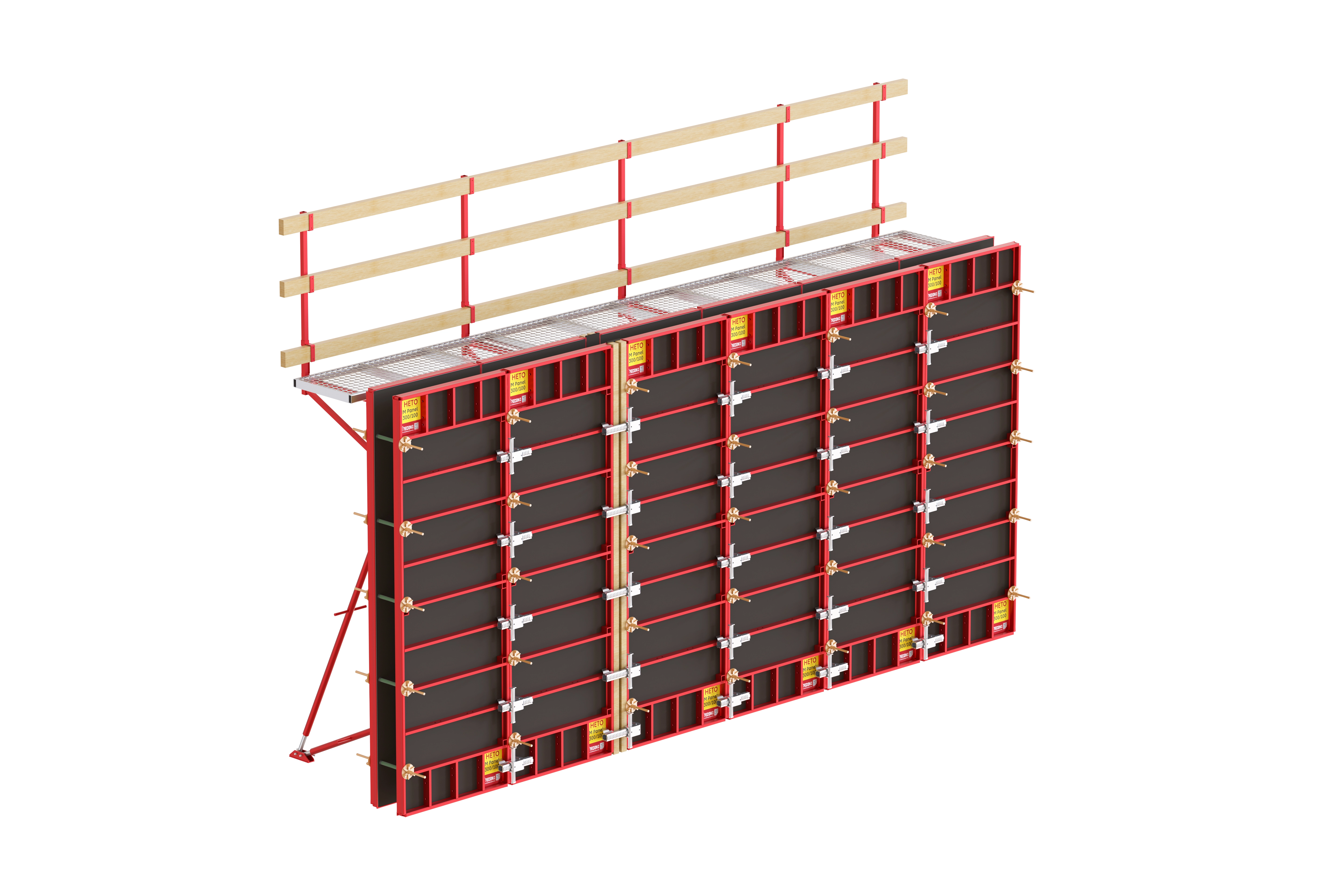

1. According to the local natural environment, the design of the load group should be carefully considered, and the calculation of the strength and stability of the steel formwork should consider the wind force in the coastal area.

2. When checking the anti-overturning stability of the steel formwork under the action of its own weight and wind load, the stability factor of checking overturning must be ≥1.3.

3. For the steel formwork with exposed structural surface, the deflection should be less than 1/400 of the span of the formwork member in the calculation; for the steel formwork with the hidden structural surface, the deflection should be less than 1/2500 of the span of the formwork member.

4. The panel deformation of the steel formwork should be less than or equal to 1.5mm.

5. The deformation of the steel prism and column hoop of the steel formwork should be less than 1/500 and B/500 (where 1 is the calculated span and B is the column width).

6. When calculating the large steel mold, in addition to the overall stiffness and strength, the strength and stiffness of the operating platform and the steel lifting ring should also be considered.

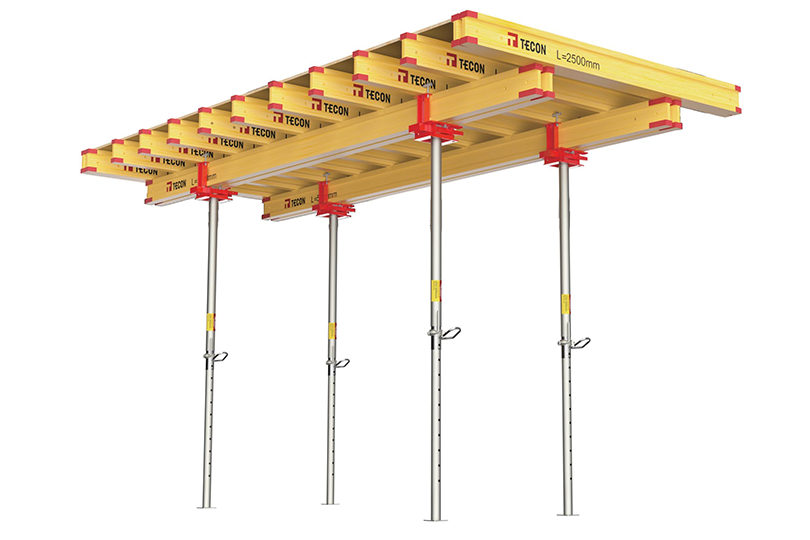

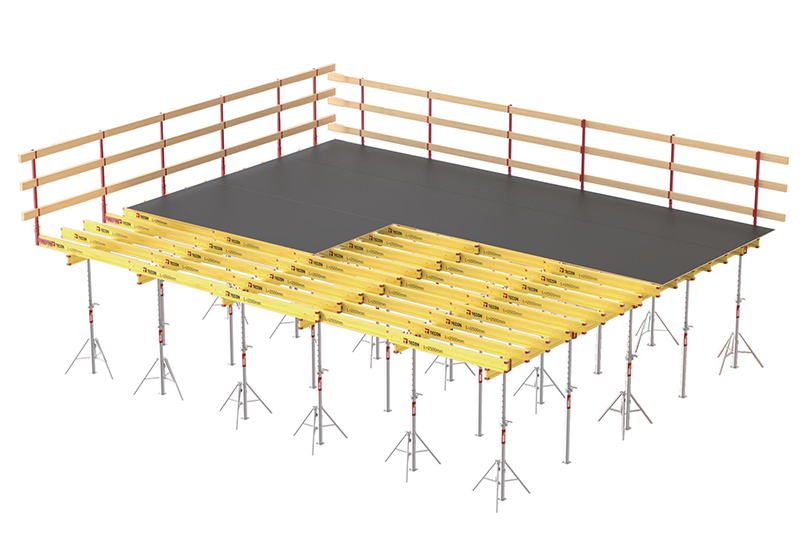

1. Good safety performance

(1) Wooden springboards are easy to crack, corrode, and burn, and are prone to safety accidents. The angle steel mesh plate is rusted and peeled off, and the hot-dip galvanized steel formwork has the advantages of anti-corrosion and fire-proof.

(2) The steel shuttering has standardly formed and arranged convex holes, with high anti-skid coefficient and good effect. The bow-shaped design on both sides of the formwork and the firm welding of the bottom rib plate further increase its strength. The 3-meter-long scaffolding board can withstand the standing of 5-6 people at the same time without deformation, and is sturdy and durable.

2. Long service life

After the wooden springboard is used for 3-5 turnovers, it can no longer be used safely and continuously, and the steel mesh formwork is also rusted and easily damaged and easily deformed. The hot-dip galvanized steel shuttering has high strength, no corrosion and no deformation, and its normal life is about 6-8 years.

3. Easy and fast installation

For the same scaffolding board, the weight of the wooden springboard is 1.5-2 times the weight of the steel scaffolding board, and the wooden board is heavier after absorbing water in rainy days, and it is extremely non-slip. During the construction of workers' novels, two people are required to lift and transport the wooden boards, while one person can carry 2-4 pieces of steel formwork, which greatly improves the work efficiency, and the high strength reduces the number of scaffolding tubes used.