Construction projects usually choose to use wooden formwork and steel formwork. Still, now more and more projects have begun to use bamboo formwork, plastic formwork and other new formwork, which construction companies gradually accept.

1. The new polymer energy-saving plastic template is low-carbon and environmentally friendly, which can achieve energy-saving recycling and realize multiple turnovers uses. The traditional wooden formwork on the construction site is basically scrapped after 3 to 5 uses, but the plastic formwork can be reused about 20 to 30 times.

2. The plastic template is more economical: From a long-term perspective, the cost of the plastic template is lower than that of the traditional template. The recycling rate of plastic formwork is more than five times that of wood formwork, and the overall cost is only 1/3 of that of wood formwork. And the plastic template material can be recycled, further saving costs. Save resources.

3. The plastic template is more convenient: the density of plastic is lower than that of wood, the weight is lighter, and it can be applied to various processes. When carrying out multiple constructions, the labour intensity is low, the transportation is convenient and safe, saving the workforce and improving construction efficiency.

During construction, according to the size of the design component, the plastic template can be processed by sawing, drilling, glueing, etc. You can process the plastic template into different shapes without affecting its normal function to satisfy the needs of supporting moulds of various shapes of building components. It can also be used in conjunction with templates of other materials.

When demolding, disassembling the plastic formwork does not need a release agent or concrete non-stick formwork. Since the surface of the plastic formwork is relatively smooth, and the splicing of the plastic formwork is relatively soft, the concrete surface after demolding will be very smooth and smooth. No secondary plastering is required. Plastic formwork does not absorb water, which is conducive to the later curing of concrete.

4. Stability and mechanical strength of the plastic template: There are no deformation and property changes in the plastic template between -20~60℃. At the same time, the plastic template also has good rigidity and hardness and strong water resistance.

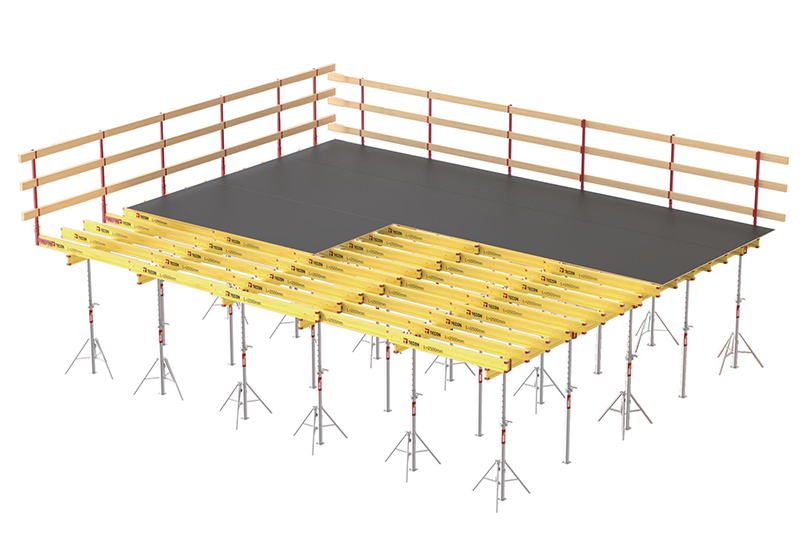

TECON provides concrete formwork (blinds) and scaffolding for global projects and has many years of experience dealing with contractors, builders and architects. We are one of the leading concrete formwork and scaffolding engineering formwork manufacturers and suppliers in China. If necessary, please consult.