(1) The building formwork is a temporary supporting structure, which is made according to the design requirements, so that the concrete structure and components are formed according to the specified position and geometrical size so as to keep their correct position and bear the weight of the building formwork itself and the external load acting on it. The purpose of the formwork project is to ensure the quality and safety of the concrete project, speed up the construction progress and reduce the cost of the project.

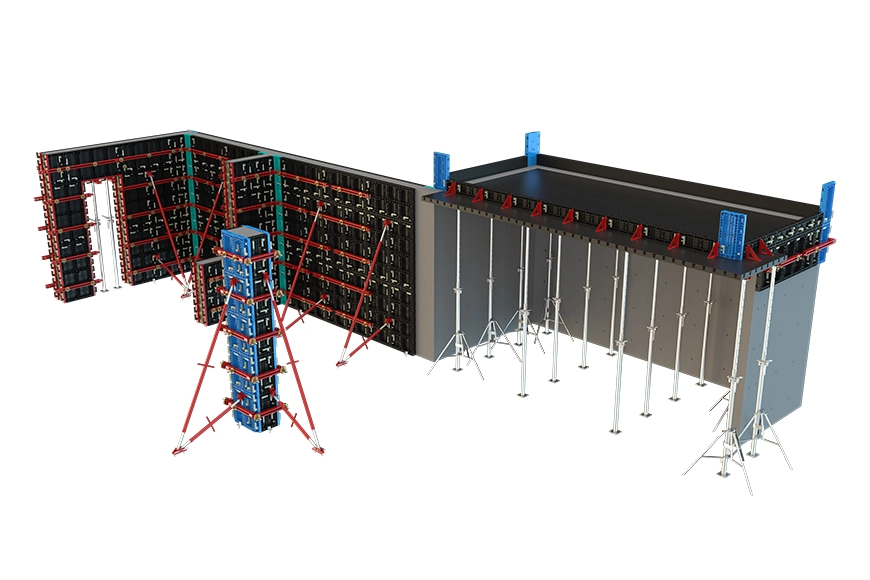

(2) The building formwork structure used in the construction of cast-in-place concrete structures is mainly composed of three parts: face plates, supporting structures and connecting pieces. The face plate is a bearing plate that directly contacts the newly poured concrete; the supporting structure is a temporary structure that supports the face plate, concrete and construction load to ensure that the building formwork structure is firmly combined without deformation or damage; the connecting piece is used to connect the face plate and the supporting structure to form a whole.

(3) Building formwork is the formwork and support formed by concrete pouring. According to the nature of the material, it can be divided into building formwork, building wood plywood, laminated board, multi-layer board, double-sided laminated board, double-sided laminated construction formwork, etc. Building formworks can be divided into cast-in-place concrete formworks, pre-assembled formworks, large formworks, and jump formworks according to construction process conditions.

(1) Ensure that the position of the building formwork is correct, and that the shape and size are fully in line with the requirements of the design drawing.

(2) Ensure that it has sufficient bearing capacity and stability to withstand various loads under various conditions during construction.

(3) The structure of the building formwork is simple, easy to install and disassemble, and flexible to use. It can meet the requirements of tying steel bars, which is suitable for centralized manufacturing, can save raw materials, improve efficiency, speed up work, and can meet the requirements of subsequent processes.

(1) The construction of beam-column houses should adopt medium-sized composite building formworks. Because of the large changes in the cross-section of beams and columns, it is not suitable to cut multi-layer boards.

(2) The wall formwork can adopt medium-sized combined building formwork. As the general requirements of the same type of high-rise building group are uniform, the medium-sized combined building formwork helps to ensure a higher turnover rate.

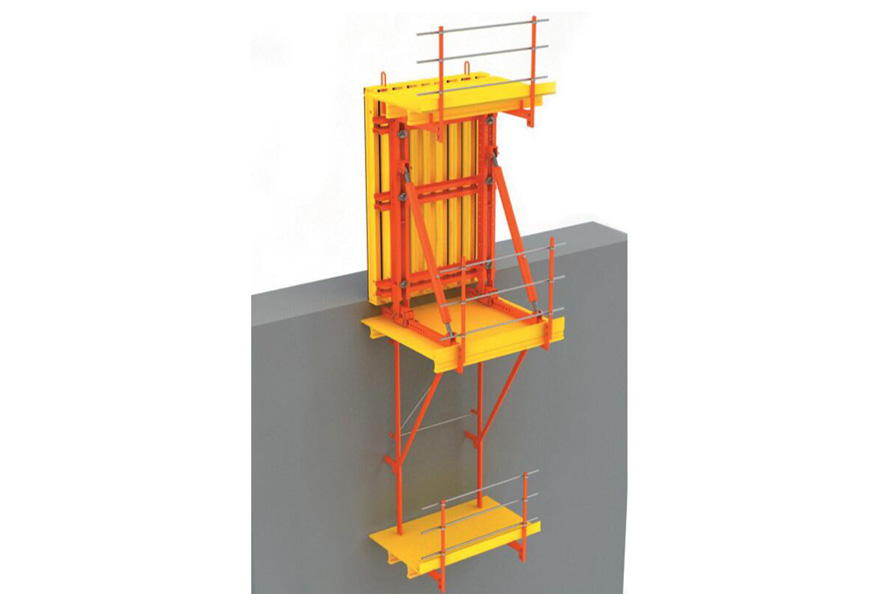

(3) The core tube of super high-rise or high-rise buildings should adopt "hydraulic climbing formwork". The climbing formwork process combines the advantages of large formwork and sliding formwork. It can rise layer by layer with the construction of the structure, and the construction speed is fast, saving space and reducing the using of tower crane. Besides, it can ensure safe high-altitude operation with no external scaffolding. In terms of construction, it is especially suitable for the construction of steel-structured concrete inner cylinder.

(4) It is recommended to use the whole multi-layer board as the floor building formwork, and try to use the phenolic-clad 15-18mm thick multi-layer building formwork. The edge of this kind of building formwork is damaged after repeated use, so it must be cut in time to ensure that the edge of the multi-layer board is flat.