The steel formwork of bridge formwork includes flat formwork, internal angle formwork, positive angle formwork, connection angle formwork, etc. The general formwork of bridge formwork includes chamfered formwork, beam hauntain formwork, flexible formwork, lap formwork, adjustable formwork and insert formwork and other special templates for bridge templates.

1. The design of the composite steel formwork should adopt the state calculation method based on the probability theory and use the design expression of the partial coefficient for the design calculation.

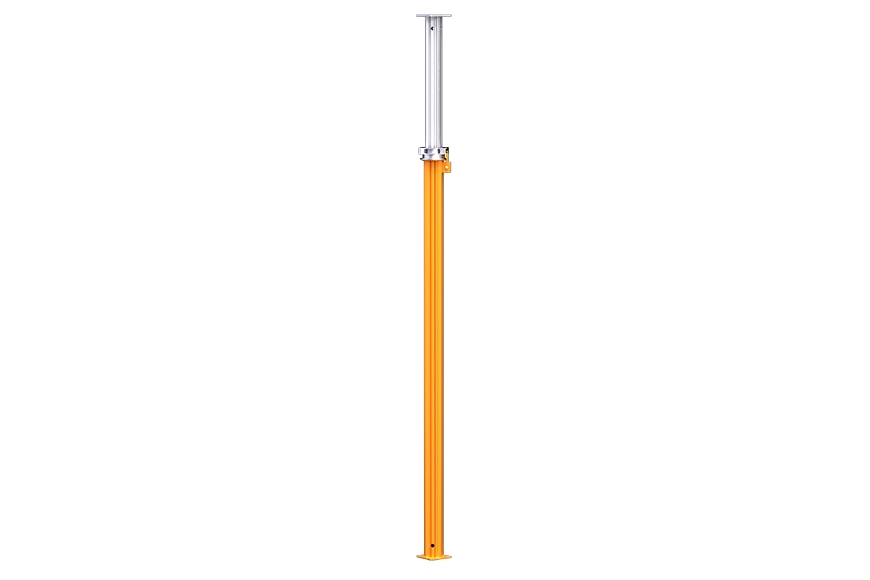

2. The steel formwork should have sufficient rigidity and strength. The rigidity and strength of the plane formwork under the specified load should meet the requirements of the specification table and its section characteristics should meet the requirements of the specification.

3. The steel formwork should be tightly assembled and disassembled, and it is convenient for flexible handling. The hole spacing of the vertical and horizontal ribs of the steel formwork should be consistent with the modulus of the formwork. The formwork can be assembled horizontally and vertically.

4. Other special formwork can be added according to the needs of engineering characteristics, but the modulus should be consistent with the modulus of the steel formwork in this specification.

5. The joints between the templates should be connected by male and female tenons.

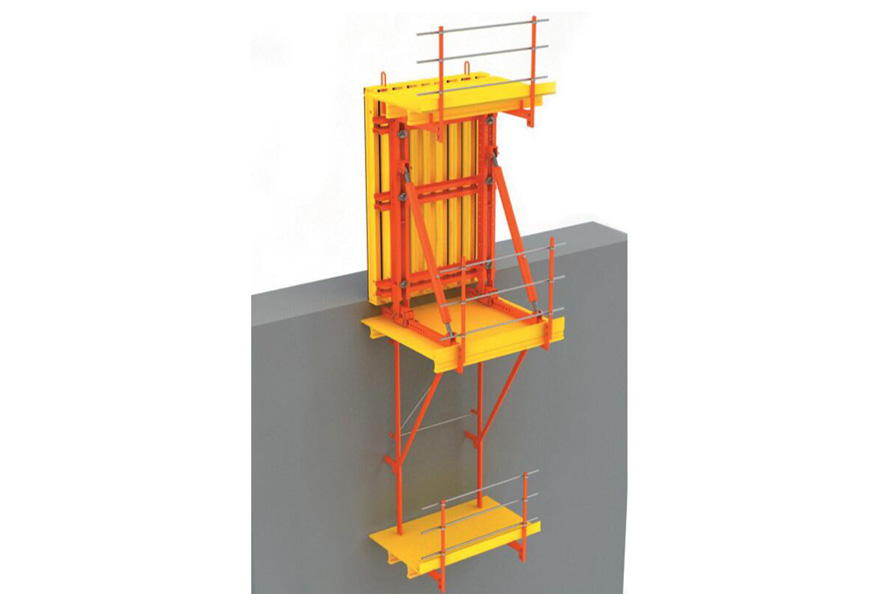

There is also bridge template calibration. Correcting the bridge template is a meticulous work. The verticality and flatness of the bridge template are corrected by the flower rail bolts and the wind-adjusting cable, and the overall stability of the bridge template is controlled. The horizontal distance between the wind cables is 2~2.5m. According to the selected material, the vertical distance is 4~5.5m, and the horizontal angle is kept at 45°~60°.

The distance between the inner and outer bridge formwork is corrected by adjusting the through-wall bolts. The manufacturer of the steel formwork system ensures that the horizontal spacing of the through-wall bolts is 750mm, and the layer spacing is 1200mm, after repeated adjustment. All indicators of the bridge formwork are in line with the construction specifications and design requirements.

1. Wear a safety helmet; dress as required.

2. The seat belt must be worn and used correctly.

3. For vertical cross operations, an isolation layer to prevent object strikes should be added.

4. It is forbidden to work at heights under severe weather conditions (such as heavy rain, heavy snow, heavy fog, strong wind).

5. Those who suffer from hypertension, heart disease, anemia, epilepsy, and limbs are not allowed to work at heights, and it is forbidden to work at heights after drinking alcohol.

As one of the leading experts in formwork and scaffolding engineering, our wide range of off-the-shelf and custom products ensures that we can provide a solution for your construction project, no matter the size or location. Welcome to consult.