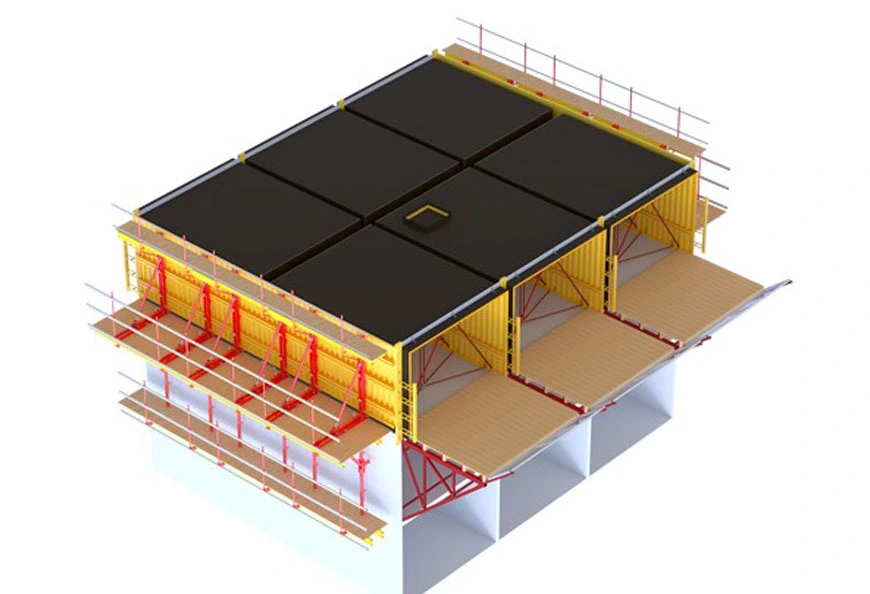

Before choosing your climbing form, we must first know the basic structure of the climbing form. The structure of climbing form, or climbing shuttering, can be divided into two parts: a support frame and a lifting frame (or door frame). The lifting frame carries the form, and the enclosure and the work bench are hung on the support frame; the support frame is a simple frame inserted in the lifting frame, the lower end of which has a fastening device which can be fixed to the hardened concrete wall under the form, and the upper end of which extends out to the top of the lifting frame. Various lifting devices can be installed to transfer all the loads of the lifting frame.

The lifting frame used for the climbing form can be modified by the lifting frame of the sliding formwork, so that the supporting frame can be inserted into it. The method of climbing form's installing formwork, lifting scaffolding and work platform on the lifting frame is basically the same as that of the sliding formwork.

The height of the climbing form can be set to 150cm, and then the combined steel formwork is staggered and assembled to the required length, which has combined rigidity and can function as a plate beam. Each time it is grouted, the wall bolts are pre-embedded according to the set spacing, which can be used as a fixed support frame or as a pair of tension bolts to resist lateral pressure.

The climbing frame of the climbing form can usually be arranged at equal distances of 150cm, and the lifting force required for each lifting frame will not exceed 10kN. The jacks used in the general sliding formwork can be applied to the climbing form. The weight of each support frame is less than 200kg, and it can be lifted individually, and the number of lifting is less than that of the lifting frame. For the pouring of each floor of the wall, the lifting frame needs to be lifted twice, and the support frame only needs to be lifted once, so it is also very easy to lift the support frame with inverted chains or pulleys.

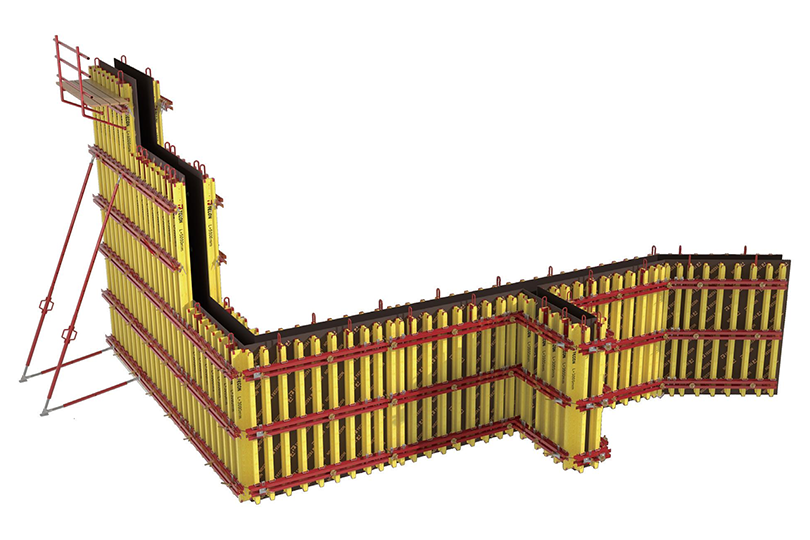

The installation methods of different lifting facilities are described as follows:

(1) Rewinding chain (or hoist)

The inverted chain is hung on the top bar of the supporting frame, and the lifting frame can be raised to the required position and then fixed with the supporting frame. When the lifting frame, formwork and newly poured concrete in the formwork are combined into one body, the lifting frame can bear a certain vertical load. At this time, the connection between the supporting frame and the wall can be removed, and the inverted chain is hung on the top bar of the lifting frame. Lift the support frame to the required height, and then fix it with the wall.

(2) Electric lead screw

A screw jack is installed between the jack of the lifting frame and the jack of the supporting frame. Due to the forward or reverse rotation of the lead screw, the supporting frame or the lifting frame can be lifted respectively.

(3) Hydraulic jack

The hydraulic jack used in the sliding formwork can be slightly modified and can also be used as a lifting device for the climbing form.