The reinforced system of aluminum formwork manufacturer mainly consists of two types of reinforcement: pulling bolt reinforcement and pulling plate reinforcement.

For pulling bolt reinforcement, it is also reinforced by backing rib. Cement support bars are added in the middle of the formwork to ensure wall thickness. The glue cups and glue pipes on the bolts also play a certain role. However, this reinforcement method has higher requirements for the design of backing ribs and the comprehensive quality of construction team.

For pulling plate reinforcement, slots are opened between formwork and formwork, and the pulling plates are reinforced by fixed nail. The backing rib only ensures the smoothness of concrete forming.

The design of aluminum formwork system is based on the construction drawings, from which the detailed drawings required for the design of aluminum formwork are sorted out.

At present, the construction technology of aluminum formwork has become mature. Therefore, many projects require more than just structural beams, plates and columns. They also need groove pressing for fire doors, push-pull doors and various channels. After the detailed drawings are sorted out and confirmed by the project, the aluminum formwork can be matched.

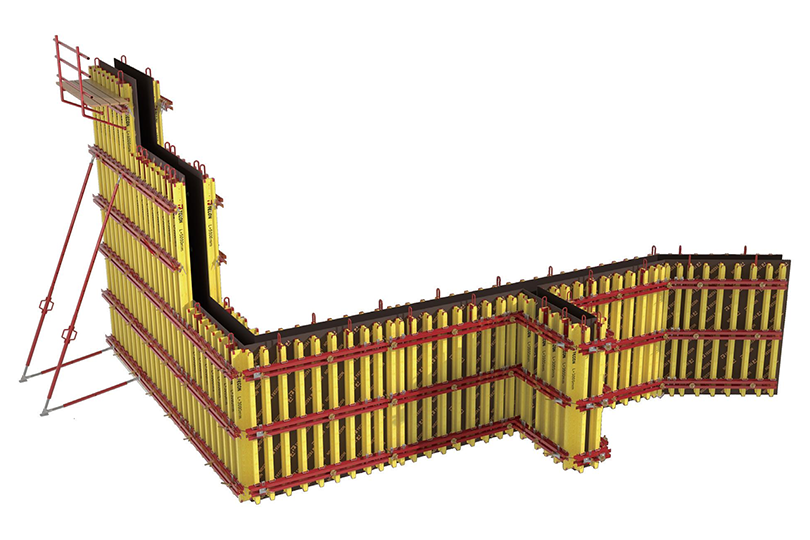

The matching process is to assemble the corresponding specifications of the formwork according to the structure marked by the detailed drawings. After assembly, the statistics are carried out. The final design results are production list, production picture, packing list and assembly drawing.

The mainstream of aluminum formwork profile is the 65 series, that is, the frame height is 65mm. The mainstream dimensions of U-plate are the largest widths of 400mm, 600mm, as well as 450mm and 500mm. Other U-plate dimensions generally decrease by 50mm. C-sections with a section of 100*150 and 150*150 are preferentially used, and some manufacturers prefer 100*100, 200*200.

There were also 54 series and 70 series in the early days, corresponding to the frame heights of 54mm and 70mm respectively.

There are two main forms of matching: 2D and 3D. In the early days, it was mainly 2D matching, that is, the formwork was matched according to the size and elevation marked by the 2D structure of the detailed drawings. For example, the slab is relatively simple if it only involves the plan size, but for such things as stairs and bay windows, which involve the size and position in the height direction, the designer's basic skills and proficiency are required, and good spatial imagination ability is also required.

In addition, the aluminum formwork that has been matched is reflected on the drawing as a two-dimensional line frame with annotation. The overall dimensions and installation dimensions cannot be fully reflected. 3D matching is relatively intuitive and simple. The aluminum formwork is assembled based on the 3D concrete model, which can also be understood as simulating the process of on-site assembly. The 3D matching model and the matched formwork are both three-dimensional solids, with overall dimensions and installation dimensions.

One form of wall plate distinguishes internal/external wall plate. The internal wall plate is 50mm higher than the concrete surface, and the external wall plate is flush with the concrete surface. The height of plate is also flush with the concrete surface. Another form does not distinguish internal/external wall plates, that is, internal/external wall plates are common, and the height of K plate is 50mm higher than the concrete surface. In terms of height direction, there are two ways: standard height and additional height.

The mainstream sizes of add-on high plates are 2400/2500/2600mm. The corner of the floor C-section is generally preferred to have a section of 100mm or 150mm in length and plane, and the standard floor plate template is mostly 1100mm or 1200mm in length. The width of the keel is commonly 100mm and 150mm, and the mainstream length of the supporting head is 200mm. The mainstream length of the middle keel is 1000mm. Some manufacturers choose 1100mm or other specifications.

As one of the leading experts in the field of formwork and scaffolding engineering, our extensive range of ready-made and custom products ensure that we can provide solutions to your construction projects, no matter how big or small or where they are located. Feel free to inquire.