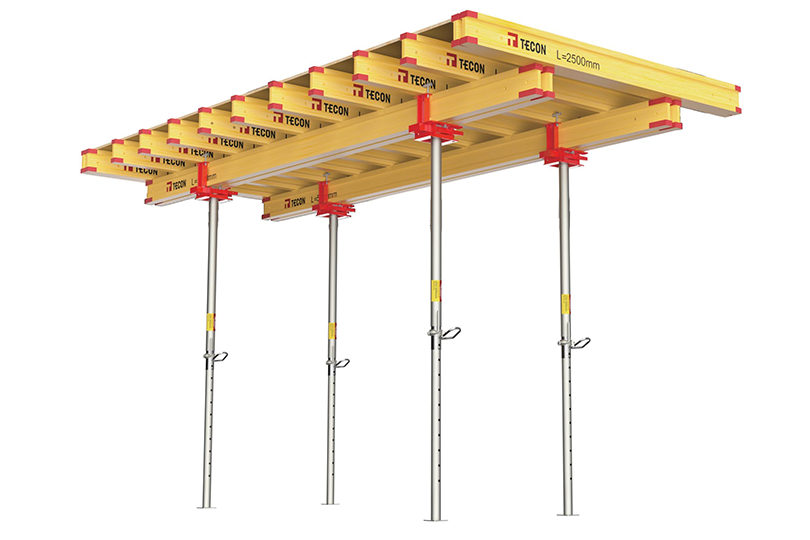

The characteristics of beams are large span, small width and large height. Therefore, the beam formwork and beam formwork system often have the characteristics of good stability, sufficient strength and rigidity, and no distortion in excess of what is allowed in the specification is allowed.

⑴ The beam formwork should be installed after checking the elevation of beam bottom and correcting the position of the axis.

⑵ The bottom of the beam is supported by top braces (pipa braces). The spacing between the top braces depends on the cross-section of the beam, generally 0.8 to 1.2m. Between the top braces, horizontal tie rods and scissor braces should be set up so that they can be pulled together into one body. When the height of the bottom of the beam is greater than 6m from the ground, a bent frame or scaffolding should be installed; In order to ensure the solid support of the top brace, pads and wedges should be set on the tamped ground.

⑶ Clamping wood should be set under the beam side formwork to clamp the beam side formwork with the bottom formwork, and nail it to the top support. Brackets are set on the upper mouth of the beam side formwork. The brackets can be fixed by pulling up (upper mouth on the pull) or under bracing (supporting on the top brace). When the beam height is ≥700mm, additional diagonal bracing or split bolt should be added to the middle of the beam for fixation.

⑷ When the span of the beam is ≥4m, the middle span of the beam formwork shall be arched, and the arching height shall be 1 to 3% of the span of the beam.

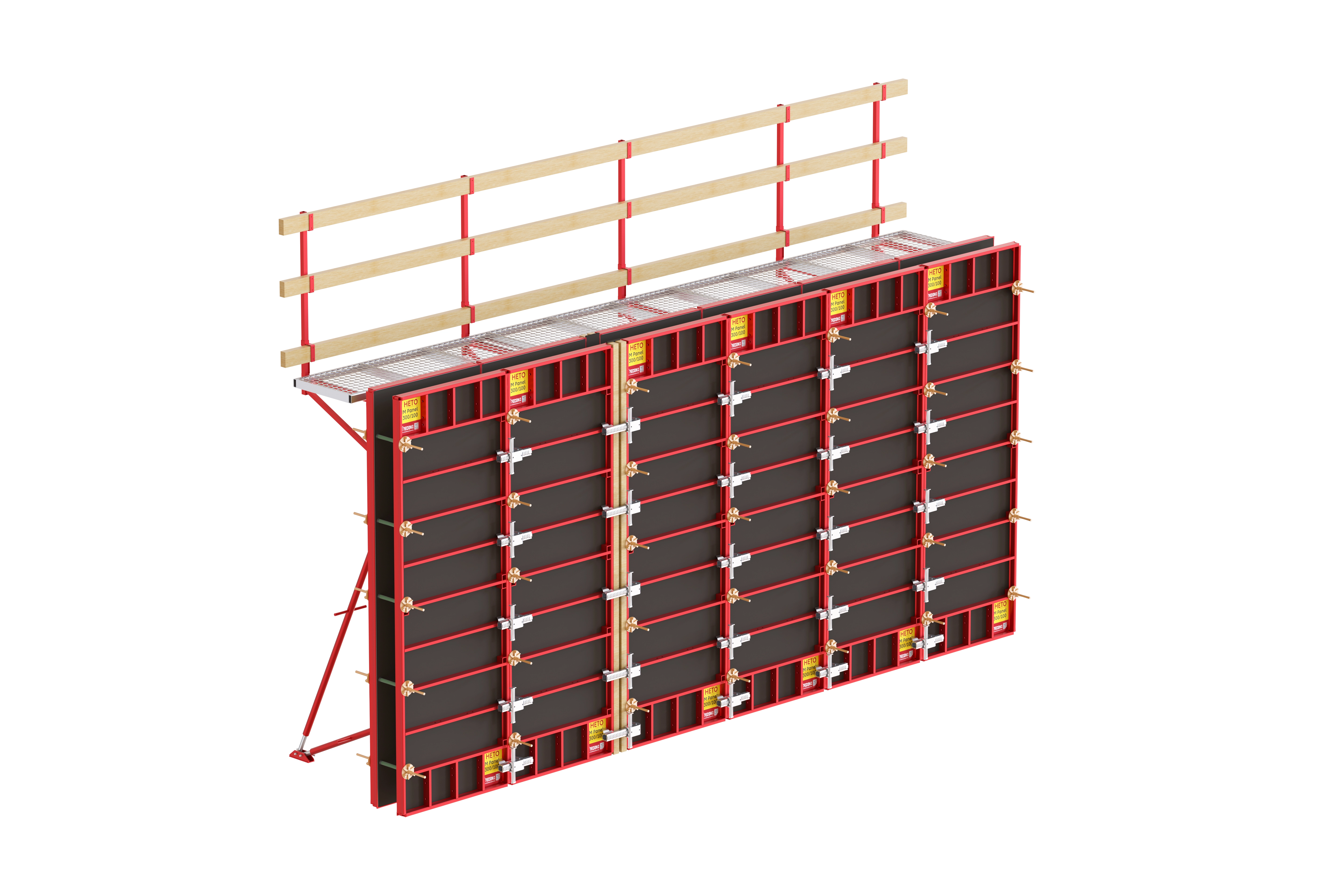

⑴ When the wall formwork is installed, one side formwork is usually first erected according to the side line and temporarily supported and fixed, and the other side formwork is erected after the wall reinforcement is tied up.

⑵ The split bolts of the wall formwork should be equipped with internal bracing sleeves (except for waterproof concrete). First, it can ensure the repeated use of the split bolts, and second, it can control the thickness of the wall.

⑶ Formwork reserved for door and window openings should have a taper, which should be installed firmly, not easy to deform, and easy to remove.

⑷ When the height of the wall formwork is large, one side of the formwork should be set aside for support in sections. If it cannot be supported in sections, the door panel should be set on the pouring side. The method of leaving and setting is the same as that of the column formwork. The horizontal spacing of the door panels is generally 2.5m.

⑸ The inner sleeve formwork set in the formwork which is reserved for the wall hole should be equipped with exhaust holes.