The wall shuttering system is an indispensable and crucial component in modern construction projects, widely used in the construction of concrete walls. It not only impacts the quality of the wall formation but also directly influences construction efficiency, safety, and cost control. With the development of industrialized construction, the wall shuttering system has gradually evolved towards standardization, modularization, and high-strength design, becoming a key tool for improving construction quality and efficiency.

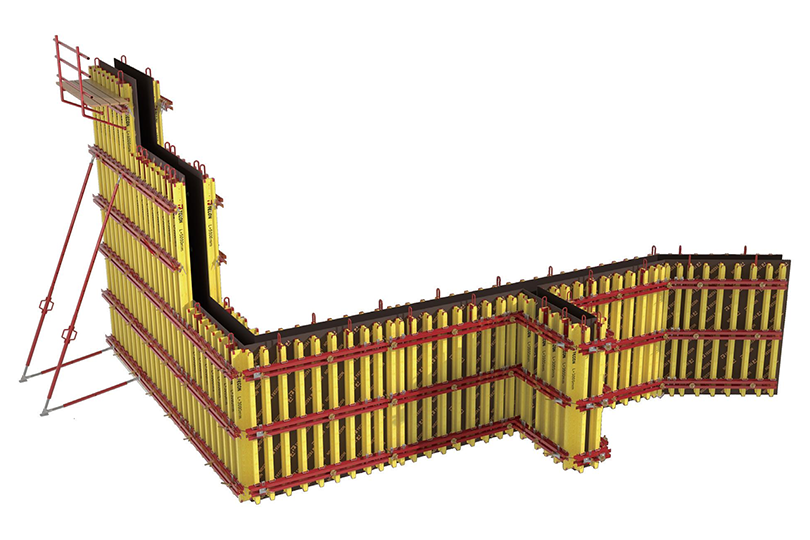

A wall shuttering system refers to a temporary formwork and support system built during concrete wall construction to ensure the quality of the concrete formation. The system includes form panels, support components, connectors, and reinforcement systems. The main function of the system is to maintain the required shape during the pouring and hardening of the concrete, while withstanding the lateral pressure of the concrete and the construction load.

Depending on the materials and structural design, wall shuttering can be made from wood, steel, aluminum alloy, and plastic. In actual construction, composite formwork or standardized formwork systems are often used to achieve the goals of reusability and high construction efficiency.

A complete wall shuttering system typically includes the following key components:

Form Panel: In direct contact with the concrete, determining the surface quality of the wall. Common materials include plywood, steel plates, and aluminum plates.

Support System: Provides vertical and horizontal support, ensuring the formwork remains undistorted. Common forms include steel braces and tie rods.

Connectors and Fasteners: Used to connect and secure the form panels together, ensuring the overall stability of the system.

Reinforcement Devices: Such as stiffeners and support rods, used to increase the load-bearing capacity and stability of the system.

Improved Construction Efficiency: Standardized and pre-designed formwork allows for rapid installation and removal, significantly shortening construction time.

Enhanced Wall Quality: The formwork system ensures good rigidity and smoothness, ensuring uniform concrete formation and reducing the need for secondary plastering work.

Strong Reusability: Particularly with aluminum and steel formworks, these systems can be reused multiple times, greatly reducing long-term construction costs.

Higher Safety: The well-designed wall shuttering system, along with its support system, provides strong overall stability, improving construction safety.

Environmentally Friendly: Through standardized production and repeated use, material waste is minimized, aligning with the principles of green building development.