Pillar wood formwork is a kind of mold that replaces traditional steel formwork. It is highly respected for its lightness, simplicity, low price and good demoulding effect. Except for the fly in the ointment of turnover, it is almost perfect. Formwork supply - how much does a column formwork cost per square meter, which has become a widely concerned issue for construction units.

In this way, the space that shelters the wind and rain can not be reinforced and built. From the appearance of its design concept until the building can finally be put into use, many processes need to go through in the middle, and in these processes, the pillar wood The selection and use of templates is actually a very critical part.

The wooden post formwork is made of good birch poplar, which is characterized by lighter weight than ordinary poplar, high strength, good toughness and easy construction.

The pillar wood formwork is made of plywood with a large surface, and the inner and outer epoxy resin film is smooth and waterproof and has a certain air permeability. The column timber formwork is easy to operate, and the concrete wall columns produced are not only smooth but also well formed, with good vision and feel. Easy to store for multiple uses.

When supporting the column timber formwork, there will be different assembling methods, and for the products in the wholesale of the column timber formwork, it must be reasonably selected and used.

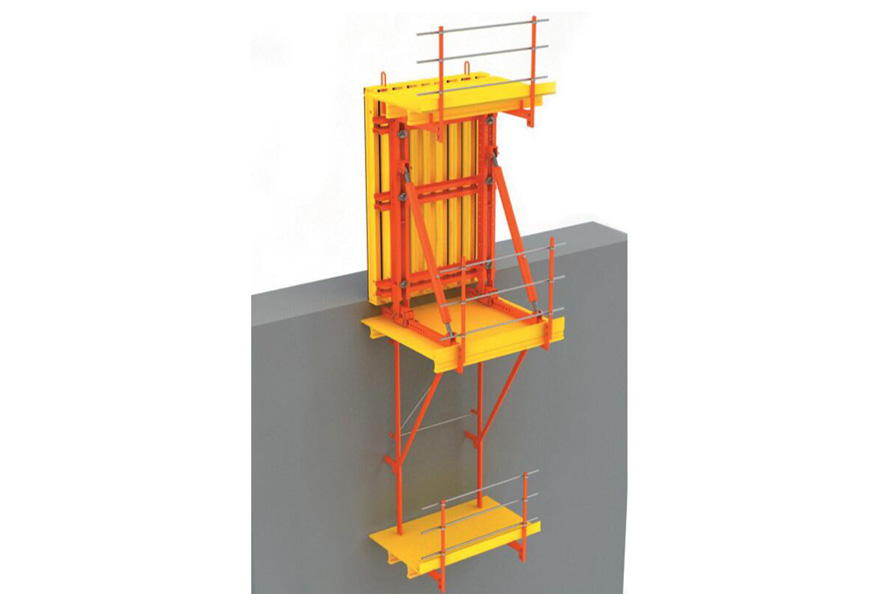

The first is the method of assembling a single piece in place. First, place the four-sided formwork of the first section of the column in place, and use the connecting corner module to assemble. Then use the upper corner mold connector attached to the first section of the formwork as the benchmark, and use the same method to assemble the second section of the formwork until the full height of the column.

There is also a method of single-piece pre-assembly, which is to hoist the pre-assembled single-piece formwork in advance and make temporary support after checking its diagonal, flatness of plate edge and external dimensions. Immediately, the second section of the template is hoisted into place, and the U-shaped card is combined with the first template to form, and at the same time, it is supported.

The pre-assembly method can also be used, which can speed up the construction speed and improve the installation quality of the column timber formwork, but the premise is that there must be suitable hoisting equipment and a larger assembly site.

1. There are positive and negative differences between high-quality plywood. When selecting, the plywood should have a clear wood grain, the front should be smooth and smooth, not rough, and should be smooth and non-stagnant;

2. High-quality plywood should not have defects such as damage, bumps, hard wounds, and scars;

3. High-quality plywood has no degumming phenomenon;

4. Some plywood of high-quality templates are made by pasting two veneers with different textures together, so in the selection, it should be noted that the joints of the plywood should be tight and there should be no unevenness;

5. When choosing plywood for column timber formwork, you should pay attention to selecting plywood that does not loose glue. If the sound is brittle when knocking on each part of the plywood, it proves that the quality is good, and if the sound is dull, it means that the plywood has been loose.

The use of column timber formwork has brought us an increase in efficiency, allowing us to shorten the construction period, which means that our costs are reduced. Therefore, the use of column timber formwork has improved the efficiency of formwork in the construction industry.