With the development of the economy, newer requirements are put forward for road traffic safety. Road and bridge construction is an important part of traffic construction. As an important applied material in bridge construction, bridge formwork has an important impact on the quality and strength of bridge construction. Especially during construction, the quality and strength of bridge formwork are more obvious.

In addition, there is an important link in the construction of bridge formwork hoisting. Let's discuss the process of hoisting this bridge formwork.

1. The bridge formwork is configured according to the design drawings, and then the bridge formwork is assembled and sorted. After cleaning, brush the salad oil. When brushing, ensure that the oil layer is uniform (not too thick), does not flow, and does not leak.

2. The polishing of the bridge formwork should be done, the surface should be smooth and smooth, and the corners of the formwork must be straight, flat and clean, and stacked in layers, which is easy to control and used in the same part, which is conducive to controlling the tightness and tightness of the joints of the combined bridge formwork. flatness.

3. When hoisting the bridge formwork, a special person should command the crane, and the signal is clear; when hoisting, the reinforcement measures on the outside of the bridge formwork should be fully considered.

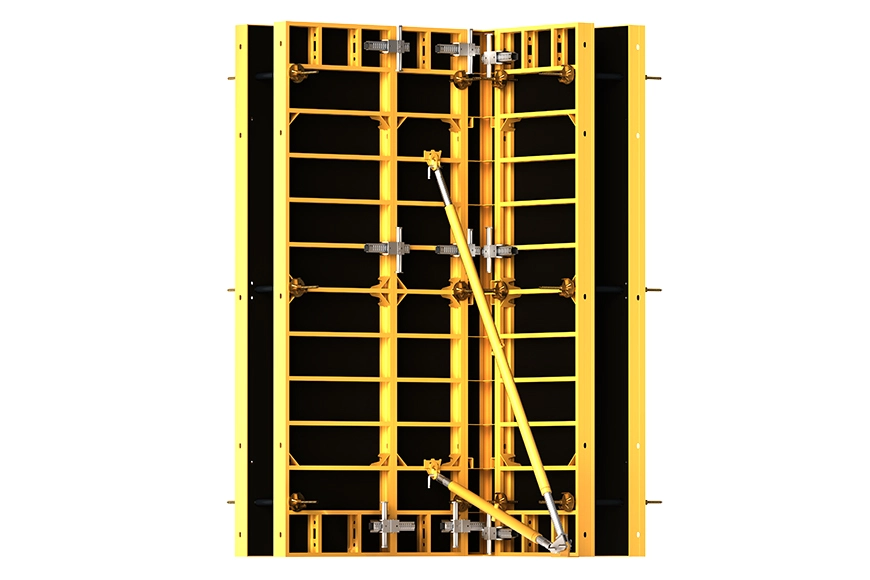

4. First hoist the plane bridge formwork, and then hoist the arc formwork. After the bridge formwork is in place, the outer side of the bridge formwork is reinforced with diagonal braces. After adjustment, it is connected and fixed with the pier body formwork, and then the left and right side formwork is hoisted.

5. Each bridge formwork should be in place according to its number, and cannot be mixed. After the bridge formwork is in place, double-sided tape should be attached between the bridge formwork blocks and between the layers, which can effectively prevent leakage during the pouring process. pulp phenomenon.

6. The edge of the tape should be flush with the edge of the bridge formwork. If it is uneven, there will be misalignment or grooves, which will affect the appearance quality of the concrete. After the bridge shuttering is all assembled, the overall reinforcement is carried out.

The above are the 6 process steps of bridge formwork hoisting. You can refer to it during construction to learn more about the technical knowledge of bridge formwork. Welcome to inquire.

As one of the leading experts in formwork and scaffolding engineering, our wide range of off-the-shelf and bespoke products ensures that we can provide a solution for your construction project, no matter the size or location.

With the expertise of our R&D team, and our technical team members on-site to assist you when necessary, and knowing that our solutions are always cost-effective, you can rest assured that from first contact to construction completion, we are always there to support you. Welcome to consult.