Steel formwork is often used in construction projects. Due to construction methods or the influence of stress intensity, steel formwork may expand and cause leakage during pouring.

Expansion is most likely to occur at the hole of the wall. The main reason is that the formwork is difficult to reinforce in this area. Sagging may occur at the center of the beam if it does not arch as required. Expansion is also likely to occur at the middle of the edges of the beam, especially at the outer edges of the peripheral beams.

The upper part of the beam has a plate, which cannot be tightened when reinforcing the beam. The middle part needs to be supported by braces. As the reinforcement can only be supported on the outside scaffold of the peripheral beam, it has a great impact on the formwork reinforcement, causing the steel formwork to be poorly reinforced and leading to expansion during pouring of concrete. It is easy for expansion to occur at the nodes of beams and columns, as well as at the nodes of walls and columns.

Cracks are prone to occur at the nodes, and it is difficult to control the quality of formwork reinforcement at the nodes. Either the formwork is not up to the edge or the formworks enter into each other.

In addition, the back edge or top rod of the formwork may not be able to reach the designated position during reinforcement. To prevent this, the design and load combination of the formwork generally use a wooden formwork system. Since the technical indicators of the wooden formwork are determined when the material is dry, the strength of the material will be reduced after being soaked in water. Therefore, when calculating the spacing of the reinforcing steel pipes and through bolts, 15% to 20% should be deducted from the normal calculation.

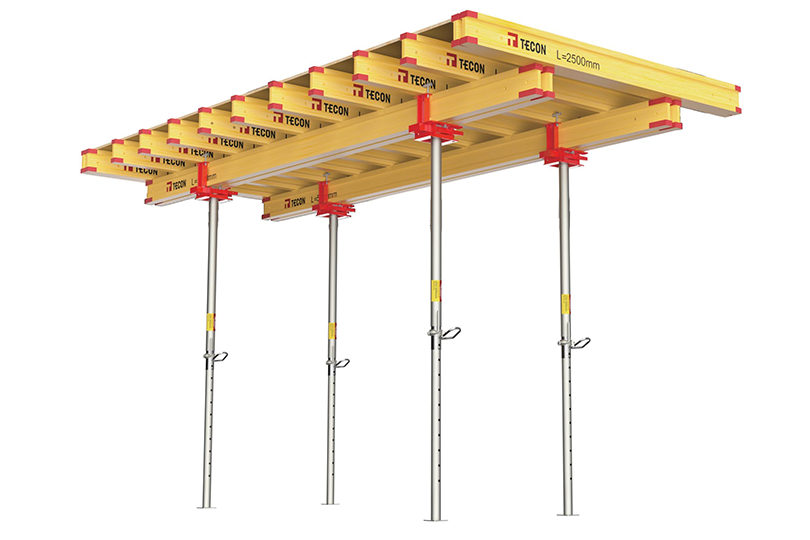

Steel formwork is a temporary support structure, which is the mold shell and support for concrete pouring. It is a new type of formwork system, such as aluminum formwork system or other types of formwork systems, with strong versatility, convenient assembly and disassembly, and a high number of turnovers in modern formwork technology. Steel formwork is a steel formwork used for concrete pouring, which can be used multiple times and has a beautiful appearance after pouring, making it widely used in the construction industry.

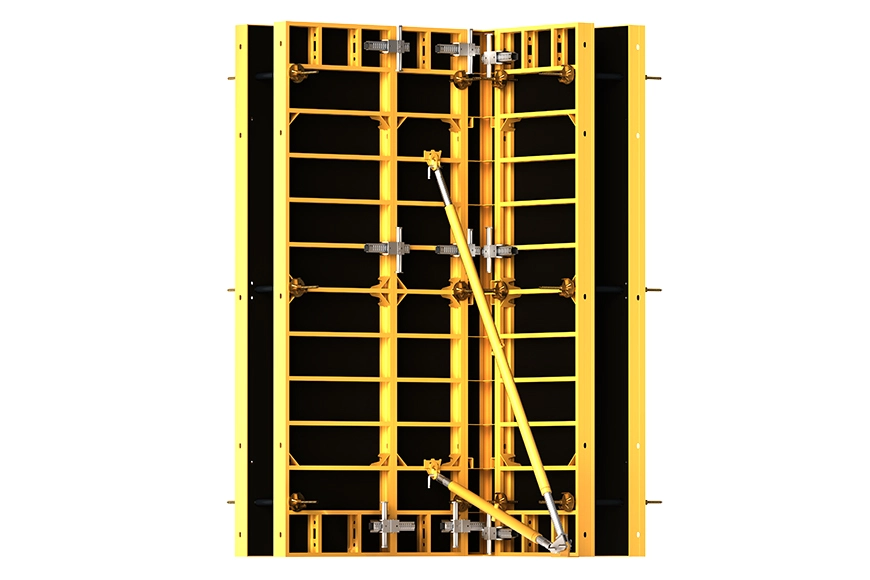

When designing and manufacturing bridge steel formwork, it is required to have sufficient strength, rigidity, and stability to reliably withstand various construction loads stipulated in the formwork construction standards and ensure that deformation does not exceed the allowable range. Moreover, it should be easy to install and remove, and strive for standardization and serialization. If there are special requirements or complex operating procedures, operational regulations should be also established.

Before assembling the formwork, each component of the formwork system should be counted and visually inspected. Components with serious defects such as severe damage, collisions, and deformation should not be used.

Technical personnel should provide technical guidance at the assembly site.

All components should be connected firmly, and the assembled steel formwork should be placed neatly according to its structural characteristics to ensure stability.

With the professional R&D team and experienced technical team members from our formwork company, we will provide you with assistance on site when necessary, and you can rest assured that our solutions are always cost-effective. From the first contact to the completion of construction, we will always be there to support you. Welcome to inquire.