Bridge formwork is divided into highway bridge formwork and railway bridge formwork. According to different conditions, bridge formwork can be divided into single and double box girder (large box girder, small box girder), wo-shaped pier column, pier column formwork, pier abutment, cover beam, T-shaped bridge formwork, etc.

What principles should be followed in the design of bridge formwork? Let's take a look.

To consider whether the pouring technology in actual use is applicable and whether it can meet the quality requirements, the key points are as follows:

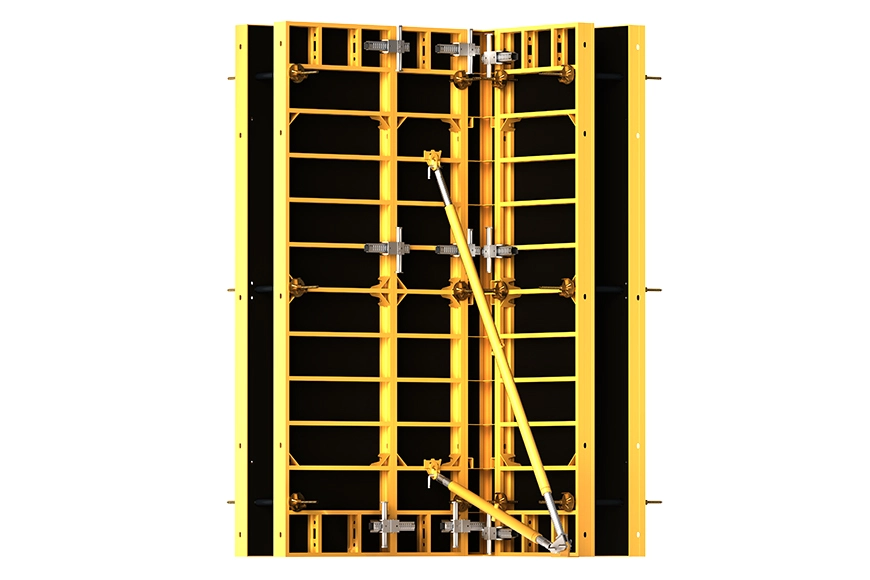

(1) The compressive strength of the steel formwork should be sufficient, not less than 2 to 3 times the actual flexural strength.

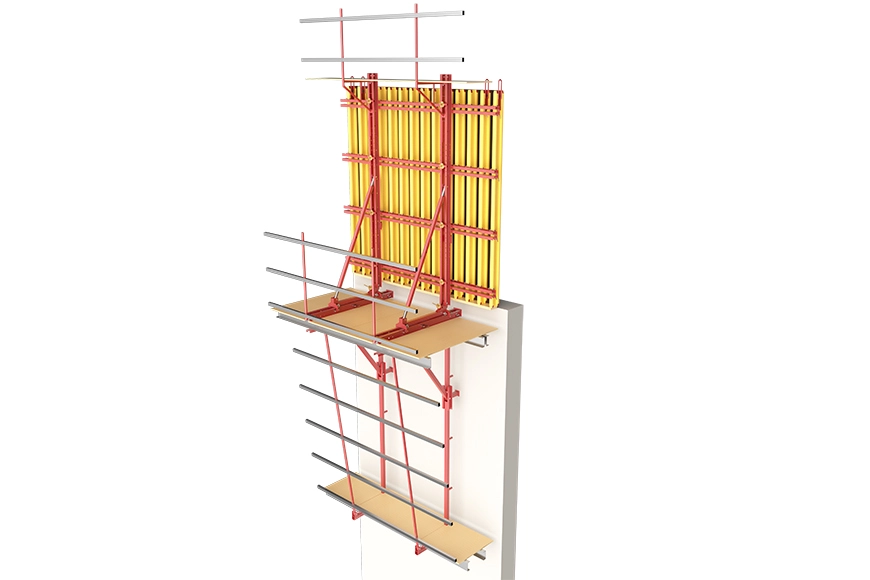

(2) Minimize seams and joints as much as possible, and use large bridge formwork as much as possible when construction conditions allow (hoisting capacity, transportation conditions, etc.) to reduce the workload of on-site assembly and disassembly, which is conducive to speeding up the construction.

(3) When designing the connection of the steel formwork, a certain number of positioning pins should be set, which is beneficial to the control of the misalignment of the bridge formwork.

(4) In order to prevent the leakage of grout, the connection parts of the two formwork should be designed in the form of yin and yang overlap.

Although the shapes and sizes of the structures are different, with the increase of the workload and the variety, they can still be divided and classified according to the main cross-sectional shape, longitudinal shape and size range (or several basic shapes). The combination of the standard section formwork and the matching section formwork makes it meet the size requirements and achieve the construction purpose, so as to reduce the investment on the bridge formwork.

This requires that the main raw materials, thickness of steel plate, thickness of rib plate, spacing of rib plate, spacing of connecting hole, hole end spacing, etc. used in this type of bridge steel formwork should be relatively fixed.

In the design and calculation of bridge formwork, under the premise of ensuring sufficient rigidity and strength of the bridge formwork, we should rationally select materials, and do not blindly conservatively design and increase costs.

When designing, it is also necessary to take into account factors such as ease of transportation and disassembly, site operation environment, construction conditions (such as hoisting and lifting equipment, etc.) to ensure that the formwork can be used to the maximum extent.

As one of the leading experts in formwork and scaffolding engineering, our wide range of off-the-shelf and custom products ensures that we can provide a solution for your construction project, no matter its size or location.

With years of experience in the industry, we founded TECON in 2013, headquartered in Suzhou, China. With the expertise of our R&D team, our technical team members are there to assist you on-site when necessary, ensuring that our solutions are always cost-effective. If you have any needs, welcome to consult us.