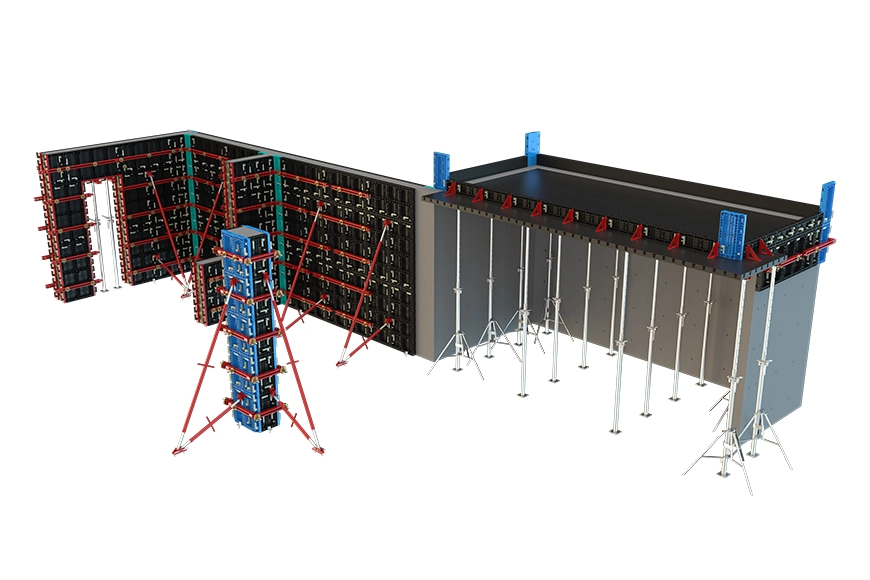

The tunnel formwork system is a system where reinforced concrete slabs and walls are poured by continuous casting of concrete. The tunnel formwork system consists of 2 half units (L-shaped) made of steel, which are connected together to form a room or unit. These rooms together form a building. In the tunnel form, the system walls and slabs are poured in a single process within a day.

The tunnel formwork system is best suited for the repetitive room design construction and construction of high-rise buildings such as apartments, hotels, and hospitals. The cycle time of the tunnel formwork system is 1 to 3 days, which is much shorter compared to other formwork systems. Therefore, the tunnel formwork system leads in saving project time, indirectly affecting the overall project cost.

Economical: For large constructions with multiple similar modular units, such as apartments, hotels, and hospitals, the tunnel formwork system is economical.

Fast and reliable: Construction becomes fast and reliable, requiring less slab cycle time with the tunnel formwork system. The construction of box-type structures can safely resist horizontal forces such as earthquakes and wind forces.

High quality: The tunnel formwork system can provide a high-quality finish as no plastering work of any type is required.

Tunnel formwork system, as an efficient, precise, and safe construction tool, is playing an increasingly important role in modern construction projects. By optimizing design, precise construction, and efficient construction methods, tunnel formwork system can not only improve project quality and speed up construction progress but also effectively control construction costs and ensure structural safety and stability of buildings.